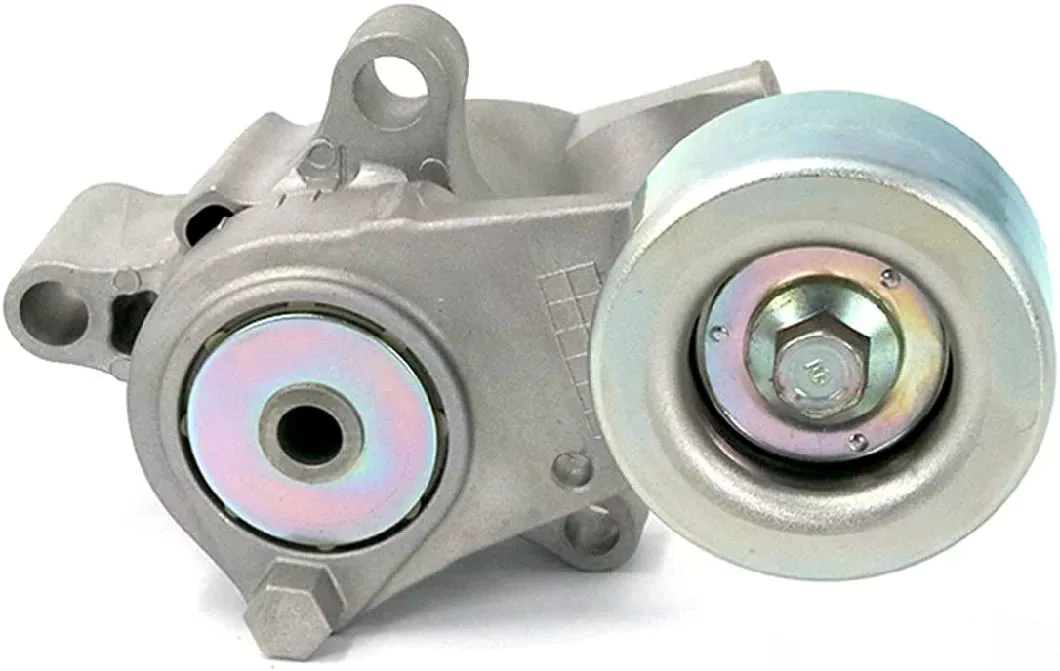

Product Description

Pulley

Specifications:

The timing pulley and timing belt of our company can be attachment or replacement of imported belt and pulley.

Please supply drawing when you order. We can also draw for clients as their supplied specification, hole, key way and width.

The tolerance of outside diameter, end bounce 7 wrap direction of pulley should conform to Form1, form 2 & form3.

Width of different specification of timing belt and pulley must conform to form4.

Outside diameter of pulleys and size should be as form’s regulation.

We can also produce pulleys even sizes are not in the form.

The material of pulley mainly composed of carbon steel, if possible aluminum alloy nylon can also be employed; If external diameter is larger than 250 mm, iron is used.

Features:

The pitch&tooth type of double sided timing belt is same as synchronous belt.

There are 2 kinds of double sided timing belt:

DA type: Arrangement symmetrical ( see section a)

dB type: Arrangement overlapping ( see section b)

Our timing pulley and timing belt is for teeth such as HTD, MXL, XL, L, H, XH, XXH, T2.5, T5, T10, T20, 3M, 5M, 8M, 14M, 20M and so on

Note: We can produce symmetrical (DA) & overlapping (dB) 2 kinds double sided timing belt, for particular specification, we can also make according to clients’ drawing or sample

Types of V-Belts and Their Properties

A v-belt’s inside length and pitch are determined by measuring along the bottom side. The included angle of a v-belt is measured from its flanks when it is extended. Most v-belt sections are 40 degrees. There are different types of v-belts, and the dimensions of each are standardized by different organizations. This article will introduce the different types of v-belts and their properties.

Notched v-belts reduce bending stress

Notched V-belts reduce bending stress by reducing the axial length of the belt by 2 or more notches. These notches are characterized by different profiles, which differ in the pitch angle and the inside length. ISO and DIN standards are followed by the manufacturers of these belts. Notched v-belts are used on industrial machinery in countries other than the US.

Compared to the standard V-belts, notched ones are designed to resist bending stress better and offer better heat dissipation. They also last longer and run cooler than standard V-belts. Furthermore, they are about 2 percent more energy efficient than their standard counterparts. Therefore, notched V-belts are a viable replacement for standard V-belts.

Notched V-belts are commonly used in industrial applications because of their low price, ease of installation, and availability of many sizes. Another advantage of notched V-belts is that they provide more wedging force and higher load capacity. Notched V-belts have a wider v-groove than flat ones, which makes them more effective for heavy-duty applications.

Notched V-belts also provide better traction. They reduce bending stress, which is beneficial for preventing fatigue and tearing of v-belts. Additionally, v-belts can be installed in an existing equipment to add more performance. And with proper maintenance and installation, notched V-belts will provide trouble-free service for many years to come.

Ribbed v-belts reduce heat dissipation

Various kinds of v-belts are available for varying applications. The more popular types are the fractional horsepower and the double-V. Fractional horsepower v-belts are designed for light-duty applications, such as machine shop equipment and household appliances. The common sectional names are 2L, 3L, 4L, and 5L. The L in each of these belts refers to the top width of the belt, multiplied by 1 eighth inch.

Unlike conventional belts, ribbed v-belts are flexible, making them ideal for use in vibrating loads. They reduce heat dissipation and can be ordered in single or multiple sets to match your application. However, ribbed v-belts should not be mounted on deep-groove sheaves, as this can cause the belt to turn over. If you use deep-groove sheaves, the risk of rupture is very high. Deep-groove sheaves can also cut banded belts. Extremely worn sheaves can also cause the belt to rip.

The 2 types of ribbed v-belts differ in their construction and application. While both types have trapezium cross-sections, they are similar in that they are made of polyurethane or other durable materials. Ribbed v-belts have an additional layer of fabric on the elastomer core for reduced noise and better heat dissipation.

Ribbed v-belts are available in a variety of sizes, including trough v-belts. Their cross-sections are categorized by their top and bottom widths and depths. The included angle of most v-belt sections is approximately 40 degrees. Different types of v-belts have different cross-sections, and these cross-sections are standardized by various organizations.

As the load increases, a ribbed v-belt will wedge into the groove and decrease the amount of friction needed to maintain the correct torque. Flat belts can track off the pulleys due to friction. However, V-belts are more stable and require less width than flat belts. The main advantage of ribbed v-belts is their increased efficiency.

The global-local finite-element model is also used to calculate the maximum and minimum J-integrals during a belt’s running cycle. The data is then used to evaluate the durability of ribbed v-belts in various applications. The numerical models used for the calculations involve a ribbed V-belt with 5 full ribs.

Cogged v-belts increase lateral rigidity to reduce belt whip

Cogged v-belts are designed for maximum performance and durability on even the harshest drive systems. These belts are made from high-modulus polyester cords that resist hardening and stretch and provide superior balance and strength. They also feature raw-edge sidewalls to reduce slip and drive vibration. In addition, they have specially-formulated rubber compounds for oil resistance. CZPT Cog-Belt offers substantial savings in downtime, energy consumption and horsepower.

A double cogged v-belt combines the benefits of cogged and double vee-belts. Its bonded reinforced tie band offers enhanced flexibility and reduces belt whipping in multiple-belt drives. Double cogged v-belt dimensions vary depending on the standards of the manufacturer. Regardless of the type, you’ll want to use a belt that is aligned correctly.

Standard v-belts are also known as wrapped or raw edge v-belts. Wrapped V-belts feature fabric covers above and beneath the cord to increase lateral rigidity and reduce belt whip. Cogged V-belts also have fabric covers to prevent wear on the core and increase the belt’s operating temperature. They’re ideally suited for applications that require high-temperature operation.

Cogged V-belts can significantly decrease energy consumption and improve power transmission capabilities. They also have a bias-cut cover stock that provides axial and lateral stability while preserving the cord integrity. A fiber loaded cogged construction offers optimum flexibility while minimizing heat buildup. It can be installed on any type of drive, including chain conveyors and industrial-grade machines.

The two-layer tie-band permanently bonds multiple belts together. This provides maximum cord support, heavy shock absorption, and stability. The belts are also engineered with patented banding processes that eliminate belt turnover and distribute load evenly across the drive. CZPT Cog-Band Belts minimize belt whip and provide stability. They also minimize belt turnover and rollover in heavy-duty industrial applications.

A classic v-belt is the most common and economical belt. Its nominal dimensions are 1/2″ to 1-11/2″ wide and 16″ to 400 inches long. The width is usually 40 degrees. Different organizations use different cross-sections to classify v-belts. The following table provides a general comparison of the 2 types. The Cogged V-Belt is designed to reduce belt whip by increasing the lateral rigidity of the belt.

Cogged v-belts provide superior environmental resistance

The patented design of the Dayco V-Belt provides maximum power transmission while combining the benefits of a cogged belt and raw-edge construction. The belt’s top cogged design helps increase air flow around it, preventing deterioration and extending its useful life. The belt’s three-ply design features neoprene impregnated fabric for superior durability and a specially-formulated polyester cord for increased strength and stability.

A variety of v-belts are available, with cogged and notched versions presenting unique characteristics. Cogged V-belts are more flexible than uncogged versions and feature ‘X’-shaped grooves for enhanced heat dissipation. Cogged V-belts are interchangeable with conventional v-belts, although their ‘X’ design is most common. Hexagonal v-belts are a popular option for applications where traction is needed.

Another type of Cogged V-belt is designed specifically for outdoor power equipment. This v-belt is brown, with smooth clutching covers. Its aramid cord is very strong and provides superior durability in adverse conditions. Cogged V-belts can withstand severe shock loads and are therefore ideal for outdoor power equipment. Furthermore, they offer superior environmental resistance, minimal stretch, and a long service life.

A Cogged V-belt is composed of tensile cords that are supported by a rubber stock. Different manufacturers use different synthetic rubber stocks for this purpose. These materials help to extend the belt’s operating temperature range and resist premature failure. In addition to tensile cords, the belt’s body is covered with a fabric cover. The fabric is treated to form a chemical bond with the core materials, which allows it to withstand constant bending.