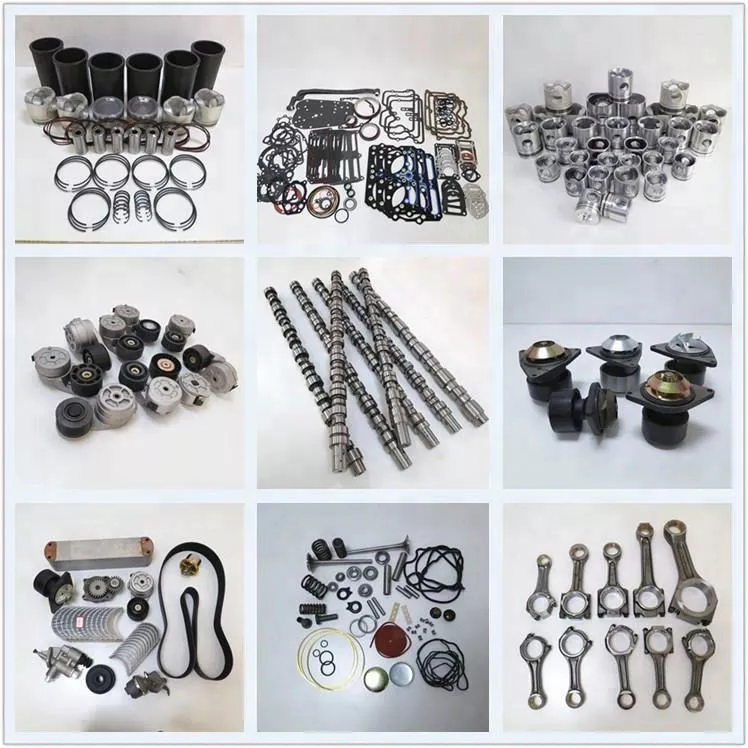

Product Description

Our Advantages

We has been providing genuine and high quality engine parts at the lowest possible cost in China, and got a high reputation from our clients due to the reliable quality, competitive price and on-time delivery.

1.Durable and high Quality.

2.Nice-looking packing.

3.Prompt delivery.

4.Wide range of parts for more models available.

5.Most competitive wholesale prices.

6.One stop buying service provided.

| PART NAME | Belt Tensioner | PART NO |

3694434 |

| ENGINE MODEL | ISG | QUALITY | GENUINE AND AFTERMARKET AVAILABLE |

| PACKING | STHangZhouRD PACKAGE | WARRENTY | 3MONTHS |

| MOQ | 1PC | PAYMENT TERM | T/T, WERTERN UNION, L/C |

| DELIVERY TIME | 7 DAYS | FOB PORT | HangZhou,HangZhou,ZheJiang , HangZhou. ETC |

Detailed Photos

Certifications

Company Profile

FAQ

Question 1:How to buy engine spare parts? First of all, please tell us the part number of the parts you need. We will supply the same parts as yours. Secondly, if you don’t know the part number, please provide parts name and engine series number, then we will check the part number through engine series number.

Question 2:How long is the delivery time? For complete engine and Power units , we need to arrange production according to the order, our general delivery time is 15-30 days. For spare parts , our general delivery time is 3-10 days.

Question 3:How to arrange delivery? Considering the large volume and weight of our products, to save the shipping cost, we generally recommend ship to your nearest port For small items and urgent orders, we can also provide air shipment and send goods to the airport in your city or your company address.

Question 4:How about Payment Methods? We suggest 30/70,T/T payment method: 30 percent down payment on placement of the order, with the remaining 70% due upon shipment. Question 5:How about Packing Methods? Normally we use wooden boxes for packaging or we can pack it according to your special needs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CCC, ISO9001, TS16949 |

|---|---|

| Standard Component: | Standard Component |

| Technics: | Casting |

| Material: | Alloy Steel |

| Type: | Tensioner Bearing |

| Application: | Construction Machinery, Tractor, Heavy Truck, Boat |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do belt tensioners enhance the overall efficiency and lifespan of belts in various applications?

Belt tensioners play a crucial role in enhancing the overall efficiency and lifespan of belts in various applications. They are designed to maintain proper tension in the belt, ensuring optimal power transmission, minimizing slippage, and reducing wear. Here’s a detailed explanation of how belt tensioners enhance efficiency and lifespan:

- Optimal Tension:

- Compensating for Belt Stretch:

- Reduced Slippage:

- Improved Belt Life:

- Reduced Maintenance:

- Noise and Vibration Reduction:

Belt tensioners are responsible for maintaining the correct tension in the belt. Proper tension is essential for efficient power transmission and preventing belt slippage. By applying the right amount of tension, belt tensioners ensure that the belt remains securely engaged with the pulleys, allowing for efficient transfer of power. This optimal tension minimizes energy losses, improves system efficiency, and reduces the risk of premature belt wear or failure due to inadequate tension.

Belts can stretch over time due to various factors such as normal wear, temperature changes, or load variations. Belt tensioners are designed to compensate for belt stretch by automatically adjusting the tension as needed. This feature helps maintain consistent belt tension and ensures proper power transmission, even as the belt elongates over its service life. By compensating for belt stretch, tensioners prevent slack in the belt, reduce the risk of belt jumping or misalignment, and extend the lifespan of the belt.

Slippage between the belt and the pulleys can lead to power loss, decreased efficiency, and accelerated belt wear. Belt tensioners help reduce slippage by maintaining the appropriate tension in the belt. The tensioner applies sufficient force to keep the belt tightly engaged with the pulleys, preventing slip under normal operating conditions. This enhanced grip improves power transmission efficiency, ensures accurate timing in timing belt applications, and minimizes the risk of belt-related issues caused by slippage.

Proper tension and reduced slippage provided by belt tensioners contribute to an extended lifespan of belts. By maintaining the correct tension, tensioners minimize the stress and strain on the belt, reducing the likelihood of premature wear or failure. They help distribute the load evenly across the belt, reducing localized wear and increasing the overall durability of the belt. Additionally, by preventing belt slippage, tensioners minimize the frictional forces that can cause heat buildup and accelerated belt degradation. This results in improved belt life and reduced maintenance costs.

Belt tensioners help reduce the need for frequent belt adjustments and maintenance. With a properly tensioned belt, the risk of belt-related issues such as misalignment, excessive wear, or premature failure is minimized. This reduces the frequency of belt replacements or adjustments, resulting in reduced maintenance downtime and costs. Belt tensioners also contribute to overall system reliability by ensuring consistent performance, reducing the need for frequent manual interventions or re-tensioning.

Improper tension or slippage in belts can lead to excessive noise and vibrations in the system. Belt tensioners help mitigate these issues by maintaining the correct tension and reducing slippage. By ensuring proper belt engagement, tensioners minimize noise generation and vibration levels, enhancing the overall comfort and performance of the system.

In summary, belt tensioners enhance the overall efficiency and lifespan of belts by maintaining optimal tension, compensating for belt stretch, reducing slippage, improving belt life, reducing maintenance needs, and minimizing noise and vibrations. By ensuring proper tension and reducing wear, belt tensioners contribute to efficient power transmission, extended belt life, and improved reliability of belt-driven systems in various applications.

What are the typical signs of improper belt tension, and how can belt tensioners address these issues?

Improper belt tension can lead to various issues in belt-driven systems. Recognizing the signs of improper tension is crucial for identifying and addressing potential problems. Belt tensioners play a crucial role in addressing these issues by adjusting and maintaining the proper tension in the belts. Here’s a detailed explanation of the typical signs of improper belt tension and how belt tensioners can address these issues:

- Slippage:

- Excessive Wear:

- Noise and Vibration:

- Overheating:

- Premature Belt Failure:

- Reduced Power Transmission Efficiency:

Slippage occurs when the belt slips on the pulleys instead of maintaining a firm grip. It can be caused by insufficient tension. Signs of slippage include a noticeable decrease in power transmission efficiency, a burning smell from friction, or visible wear on the belt and pulleys. Belt tensioners address slippage by applying the necessary force to increase the tension, improving the grip between the belt and the pulleys and minimizing slippage.

Improper tension can cause excessive wear on belts, pulleys, and other components. Insufficient tension may lead to belt slipping, resulting in accelerated wear. On the other hand, excessive tension can cause excessive stress and strain on the belt, leading to premature wear and potential damage. Belt tensioners help address excessive wear by adjusting the tension to the manufacturer’s recommended range, ensuring proper belt engagement and minimizing wear on the belt and associated components.

Improper belt tension can contribute to increased noise and vibration levels in the system. Insufficient tension may cause belt flapping or fluttering, leading to vibrations and noise. Excessive tension can create excessive forces and induce resonance, resulting in vibrations and noise as well. Belt tensioners address these issues by maintaining the correct tension, minimizing belt movement, reducing vibrations, and lowering noise levels, resulting in smoother and quieter operation.

Inadequate belt tension can cause overheating due to increased friction between the belt and the pulleys. Overheating may manifest as excessive heat radiating from the belt or pulleys, discoloration of the belt, or even belt degradation. Belt tensioners help address overheating by maintaining the proper tension, ensuring efficient power transmission and minimizing friction, which in turn reduces heat generation and helps prevent overheating issues.

Improper tension significantly increases the risk of premature belt failure. Insufficient tension can lead to belt slippage, accelerated wear, and reduced belt lifespan. Excessive tension can cause excessive stress and fatigue, leading to belt breakage or premature damage. Belt tensioners address these issues by maintaining the correct tension, distributing the load evenly across the belt, minimizing stress, and promoting longer belt life.

Improper belt tension can result in reduced power transmission efficiency. Insufficient tension leads to belt slipping, reducing the amount of power transferred from the driving pulley to the driven pulley. Excessive tension can cause increased friction and energy losses. Belt tensioners address these issues by ensuring the proper tension, maximizing the grip between the belt and the pulleys, and optimizing power transmission efficiency.

In summary, improper belt tension can manifest through signs such as slippage, excessive wear, noise and vibration, overheating, premature belt failure, and reduced power transmission efficiency. Belt tensioners address these issues by adjusting the tension to the recommended range, minimizing slippage, reducing wear, damping vibrations, preventing overheating, promoting longer belt life, and optimizing power transmission efficiency. Regular inspection and adjustment of belt tension using appropriate tensioners are essential for maintaining optimal belt performance and preventing potential issues.

What industries and machinery commonly use belt tensioners for optimal belt performance?

Various industries and machinery rely on belt tensioners to achieve optimal belt performance. Here’s a detailed explanation of the industries and machinery that commonly use belt tensioners:

- Automotive Industry:

- Industrial Machinery:

- Power Generation:

- Agricultural Equipment:

- Construction and Mining:

- HVAC and Refrigeration:

The automotive industry extensively utilizes belt tensioners in vehicles for various applications. Belt tensioners are commonly found in the engine accessory drive system, where they maintain the proper tension in the serpentine or V-belts that power components such as the alternator, air conditioning compressor, power steering pump, and water pump. Belt tensioners ensure efficient power transmission, reduce belt slippage, and contribute to the overall reliability and performance of automotive engines.

A wide range of industrial machinery relies on belt tensioners for optimal belt performance. Industries such as manufacturing, food processing, packaging, printing, and material handling use belt-driven systems for conveyor belts, production lines, pumps, compressors, and other equipment. Belt tensioners help maintain the proper tension in these applications, ensuring smooth operation, efficient power transmission, and minimizing downtime due to belt slippage or failure.

In the power generation sector, belt tensioners are commonly used in applications such as generators, turbines, and auxiliary equipment. These systems often utilize belts to transfer power between components, and the tensioners play a crucial role in maintaining proper belt tension. Belt tensioners help optimize power transmission efficiency, reduce vibrations, and enhance the overall reliability of the power generation equipment.

Agricultural machinery, including tractors, combines, and other farming equipment, often rely on belt-driven systems for various operations. Belt tensioners are utilized to maintain the tension in belts powering agricultural implements, such as harvesters, balers, and grain conveyors. By ensuring optimal tension, belt tensioners contribute to the efficient operation of agricultural equipment, improving productivity and reducing maintenance requirements.

Construction and mining industries commonly employ belt-driven systems in equipment such as excavators, loaders, crushers, and conveyor systems. Belt tensioners are used to maintain the proper tension in belts powering these machines, ensuring reliable and efficient operation in demanding environments. Belt tensioners help prevent belt slippage, reduce downtime, and contribute to the longevity of the equipment.

The HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration industries rely on belt-driven systems for various applications, including fans, blowers, compressors, and pumps. Belt tensioners are critical in maintaining the proper tension in these systems, ensuring efficient power transmission and reducing belt-related issues such as slippage or premature wear. Belt tensioners contribute to the overall performance and reliability of HVAC and refrigeration equipment.

In addition to the industries mentioned above, belt tensioners are also utilized in a wide range of other machinery and equipment, including woodworking machinery, textile machinery, marine propulsion systems, and more. The versatility and benefits of belt tensioners make them a valuable component for achieving optimal belt performance in numerous industrial and mechanical applications.

editor by CX 2024-03-15

China Best Sales Best Price Genuine Motor Parts Isg Engine Belt Tensioner 3694434 detroit axle

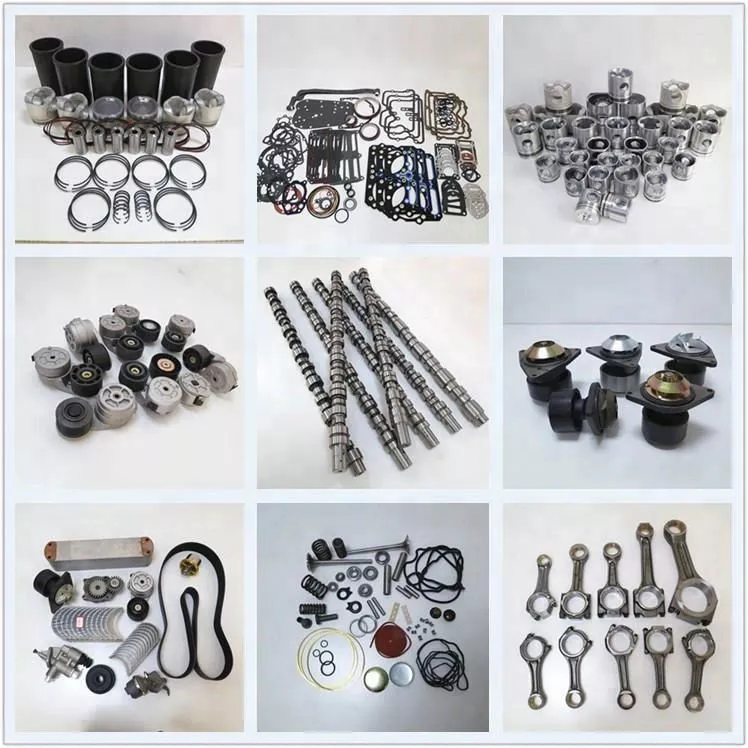

Product Description

Our Advantages

We has been providing genuine and high quality engine parts at the lowest possible cost in China, and got a high reputation from our clients due to the reliable quality, competitive price and on-time delivery.

1.Durable and high Quality.

2.Nice-looking packing.

3.Prompt delivery.

4.Wide range of parts for more models available.

5.Most competitive wholesale prices.

6.One stop buying service provided.

| PART NAME | Belt Tensioner | PART NO |

3694434 |

| ENGINE MODEL | ISG | QUALITY | GENUINE AND AFTERMARKET AVAILABLE |

| PACKING | STHangZhouRD PACKAGE | WARRENTY | 3MONTHS |

| MOQ | 1PC | PAYMENT TERM | T/T, WERTERN UNION, L/C |

| DELIVERY TIME | 7 DAYS | FOB PORT | HangZhou,HangZhou,ZheJiang , HangZhou. ETC |

Detailed Photos

Certifications

Company Profile

FAQ

Question 1:How to buy engine spare parts? First of all, please tell us the part number of the parts you need. We will supply the same parts as yours. Secondly, if you don’t know the part number, please provide parts name and engine series number, then we will check the part number through engine series number.

Question 2:How long is the delivery time? For complete engine and Power units , we need to arrange production according to the order, our general delivery time is 15-30 days. For spare parts , our general delivery time is 3-10 days.

Question 3:How to arrange delivery? Considering the large volume and weight of our products, to save the shipping cost, we generally recommend ship to your nearest port For small items and urgent orders, we can also provide air shipment and send goods to the airport in your city or your company address.

Question 4:How about Payment Methods? We suggest 30/70,T/T payment method: 30 percent down payment on placement of the order, with the remaining 70% due upon shipment. Question 5:How about Packing Methods? Normally we use wooden boxes for packaging or we can pack it according to your special needs.

| Certification: | CCC, ISO9001, TS16949 |

|---|---|

| Standard Component: | Standard Component |

| Technics: | Casting |

| Material: | Alloy Steel |

| Type: | Tensioner Bearing |

| Application: | Construction Machinery, Tractor, Heavy Truck, Boat |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do belt tensioners enhance the overall efficiency and lifespan of belts in various applications?

Belt tensioners play a crucial role in enhancing the overall efficiency and lifespan of belts in various applications. They are designed to maintain proper tension in the belt, ensuring optimal power transmission, minimizing slippage, and reducing wear. Here’s a detailed explanation of how belt tensioners enhance efficiency and lifespan:

- Optimal Tension:

- Compensating for Belt Stretch:

- Reduced Slippage:

- Improved Belt Life:

- Reduced Maintenance:

- Noise and Vibration Reduction:

Belt tensioners are responsible for maintaining the correct tension in the belt. Proper tension is essential for efficient power transmission and preventing belt slippage. By applying the right amount of tension, belt tensioners ensure that the belt remains securely engaged with the pulleys, allowing for efficient transfer of power. This optimal tension minimizes energy losses, improves system efficiency, and reduces the risk of premature belt wear or failure due to inadequate tension.

Belts can stretch over time due to various factors such as normal wear, temperature changes, or load variations. Belt tensioners are designed to compensate for belt stretch by automatically adjusting the tension as needed. This feature helps maintain consistent belt tension and ensures proper power transmission, even as the belt elongates over its service life. By compensating for belt stretch, tensioners prevent slack in the belt, reduce the risk of belt jumping or misalignment, and extend the lifespan of the belt.

Slippage between the belt and the pulleys can lead to power loss, decreased efficiency, and accelerated belt wear. Belt tensioners help reduce slippage by maintaining the appropriate tension in the belt. The tensioner applies sufficient force to keep the belt tightly engaged with the pulleys, preventing slip under normal operating conditions. This enhanced grip improves power transmission efficiency, ensures accurate timing in timing belt applications, and minimizes the risk of belt-related issues caused by slippage.

Proper tension and reduced slippage provided by belt tensioners contribute to an extended lifespan of belts. By maintaining the correct tension, tensioners minimize the stress and strain on the belt, reducing the likelihood of premature wear or failure. They help distribute the load evenly across the belt, reducing localized wear and increasing the overall durability of the belt. Additionally, by preventing belt slippage, tensioners minimize the frictional forces that can cause heat buildup and accelerated belt degradation. This results in improved belt life and reduced maintenance costs.

Belt tensioners help reduce the need for frequent belt adjustments and maintenance. With a properly tensioned belt, the risk of belt-related issues such as misalignment, excessive wear, or premature failure is minimized. This reduces the frequency of belt replacements or adjustments, resulting in reduced maintenance downtime and costs. Belt tensioners also contribute to overall system reliability by ensuring consistent performance, reducing the need for frequent manual interventions or re-tensioning.

Improper tension or slippage in belts can lead to excessive noise and vibrations in the system. Belt tensioners help mitigate these issues by maintaining the correct tension and reducing slippage. By ensuring proper belt engagement, tensioners minimize noise generation and vibration levels, enhancing the overall comfort and performance of the system.

In summary, belt tensioners enhance the overall efficiency and lifespan of belts by maintaining optimal tension, compensating for belt stretch, reducing slippage, improving belt life, reducing maintenance needs, and minimizing noise and vibrations. By ensuring proper tension and reducing wear, belt tensioners contribute to efficient power transmission, extended belt life, and improved reliability of belt-driven systems in various applications.

What are the typical signs of improper belt tension, and how can belt tensioners address these issues?

Improper belt tension can lead to various issues in belt-driven systems. Recognizing the signs of improper tension is crucial for identifying and addressing potential problems. Belt tensioners play a crucial role in addressing these issues by adjusting and maintaining the proper tension in the belts. Here’s a detailed explanation of the typical signs of improper belt tension and how belt tensioners can address these issues:

- Slippage:

- Excessive Wear:

- Noise and Vibration:

- Overheating:

- Premature Belt Failure:

- Reduced Power Transmission Efficiency:

Slippage occurs when the belt slips on the pulleys instead of maintaining a firm grip. It can be caused by insufficient tension. Signs of slippage include a noticeable decrease in power transmission efficiency, a burning smell from friction, or visible wear on the belt and pulleys. Belt tensioners address slippage by applying the necessary force to increase the tension, improving the grip between the belt and the pulleys and minimizing slippage.

Improper tension can cause excessive wear on belts, pulleys, and other components. Insufficient tension may lead to belt slipping, resulting in accelerated wear. On the other hand, excessive tension can cause excessive stress and strain on the belt, leading to premature wear and potential damage. Belt tensioners help address excessive wear by adjusting the tension to the manufacturer’s recommended range, ensuring proper belt engagement and minimizing wear on the belt and associated components.

Improper belt tension can contribute to increased noise and vibration levels in the system. Insufficient tension may cause belt flapping or fluttering, leading to vibrations and noise. Excessive tension can create excessive forces and induce resonance, resulting in vibrations and noise as well. Belt tensioners address these issues by maintaining the correct tension, minimizing belt movement, reducing vibrations, and lowering noise levels, resulting in smoother and quieter operation.

Inadequate belt tension can cause overheating due to increased friction between the belt and the pulleys. Overheating may manifest as excessive heat radiating from the belt or pulleys, discoloration of the belt, or even belt degradation. Belt tensioners help address overheating by maintaining the proper tension, ensuring efficient power transmission and minimizing friction, which in turn reduces heat generation and helps prevent overheating issues.

Improper tension significantly increases the risk of premature belt failure. Insufficient tension can lead to belt slippage, accelerated wear, and reduced belt lifespan. Excessive tension can cause excessive stress and fatigue, leading to belt breakage or premature damage. Belt tensioners address these issues by maintaining the correct tension, distributing the load evenly across the belt, minimizing stress, and promoting longer belt life.

Improper belt tension can result in reduced power transmission efficiency. Insufficient tension leads to belt slipping, reducing the amount of power transferred from the driving pulley to the driven pulley. Excessive tension can cause increased friction and energy losses. Belt tensioners address these issues by ensuring the proper tension, maximizing the grip between the belt and the pulleys, and optimizing power transmission efficiency.

In summary, improper belt tension can manifest through signs such as slippage, excessive wear, noise and vibration, overheating, premature belt failure, and reduced power transmission efficiency. Belt tensioners address these issues by adjusting the tension to the recommended range, minimizing slippage, reducing wear, damping vibrations, preventing overheating, promoting longer belt life, and optimizing power transmission efficiency. Regular inspection and adjustment of belt tension using appropriate tensioners are essential for maintaining optimal belt performance and preventing potential issues.

What industries and machinery commonly use belt tensioners for optimal belt performance?

Various industries and machinery rely on belt tensioners to achieve optimal belt performance. Here’s a detailed explanation of the industries and machinery that commonly use belt tensioners:

- Automotive Industry:

- Industrial Machinery:

- Power Generation:

- Agricultural Equipment:

- Construction and Mining:

- HVAC and Refrigeration:

The automotive industry extensively utilizes belt tensioners in vehicles for various applications. Belt tensioners are commonly found in the engine accessory drive system, where they maintain the proper tension in the serpentine or V-belts that power components such as the alternator, air conditioning compressor, power steering pump, and water pump. Belt tensioners ensure efficient power transmission, reduce belt slippage, and contribute to the overall reliability and performance of automotive engines.

A wide range of industrial machinery relies on belt tensioners for optimal belt performance. Industries such as manufacturing, food processing, packaging, printing, and material handling use belt-driven systems for conveyor belts, production lines, pumps, compressors, and other equipment. Belt tensioners help maintain the proper tension in these applications, ensuring smooth operation, efficient power transmission, and minimizing downtime due to belt slippage or failure.

In the power generation sector, belt tensioners are commonly used in applications such as generators, turbines, and auxiliary equipment. These systems often utilize belts to transfer power between components, and the tensioners play a crucial role in maintaining proper belt tension. Belt tensioners help optimize power transmission efficiency, reduce vibrations, and enhance the overall reliability of the power generation equipment.

Agricultural machinery, including tractors, combines, and other farming equipment, often rely on belt-driven systems for various operations. Belt tensioners are utilized to maintain the tension in belts powering agricultural implements, such as harvesters, balers, and grain conveyors. By ensuring optimal tension, belt tensioners contribute to the efficient operation of agricultural equipment, improving productivity and reducing maintenance requirements.

Construction and mining industries commonly employ belt-driven systems in equipment such as excavators, loaders, crushers, and conveyor systems. Belt tensioners are used to maintain the proper tension in belts powering these machines, ensuring reliable and efficient operation in demanding environments. Belt tensioners help prevent belt slippage, reduce downtime, and contribute to the longevity of the equipment.

The HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration industries rely on belt-driven systems for various applications, including fans, blowers, compressors, and pumps. Belt tensioners are critical in maintaining the proper tension in these systems, ensuring efficient power transmission and reducing belt-related issues such as slippage or premature wear. Belt tensioners contribute to the overall performance and reliability of HVAC and refrigeration equipment.

In addition to the industries mentioned above, belt tensioners are also utilized in a wide range of other machinery and equipment, including woodworking machinery, textile machinery, marine propulsion systems, and more. The versatility and benefits of belt tensioners make them a valuable component for achieving optimal belt performance in numerous industrial and mechanical applications.

editor by CX 2023-11-27

China Hot selling Round V Grooved PVC Plastic Timing Belt Tensioner Sheave Pulley for Engine Motor near me manufacturer

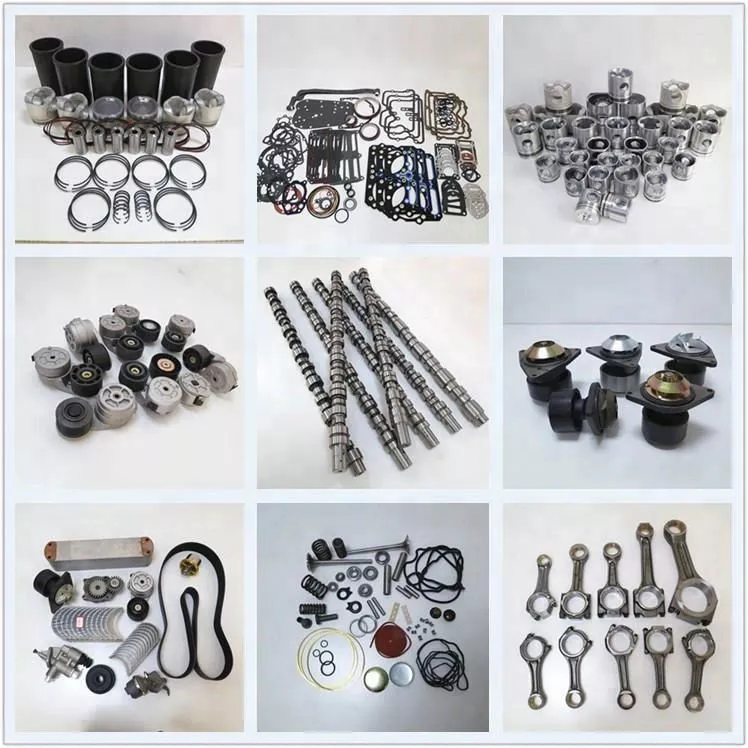

Product Description

Round V Grooved PVC Plastic Timing Belt Tensioner Sheave Pulley For Engine Motor

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | EPDM,Silicone,FKM,NBR,NR,SBR,IR,IIR,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Compression molding, injection molding, vacuum vulcanizing, extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

Why Choose Us

Our Machine

Product Range

Contact Us

How to Fix a Faulty Drive Belt Tensioner

If you’re experiencing grinding, squeaking, or other unusual sounds from your car, your drive belt tensioner may be the culprit. In this article, we’ll discuss why a failed drive belt tensioner may need to be replaced and how to fix it. Once you have determined that your belt tensioner is faulty, you can use a Wrench to remove it and replace it with a new one. After you replace the belt tensioner, it will no longer be making noises.

Problems with timing belt tensioner

Whenever your engine is making strange noises, it is likely that the timing belt tensioner is causing the problem. A bad timing belt tensioner is a big cause of such sounds, as the timing of the engine is critical. When the belt is moving properly, the camshaft and crankshaft are perfectly synchronized, and the valves work in perfect sync during the intake and exhaust strokes of each cylinder.

Other signs of a worn tensioner include rust bleeding and dripping. Usually, rust will appear at the mounting bolts and “stops” on the tensioner. Other symptoms of a worn timing belt tensioner are noise, resistance, and roughness. If any of these symptoms are present, it’s important to get the car fixed as soon as possible. Troubleshooting problems with timing belt tensioner is an easy process if you know the symptoms.

If your car starts making squeaking or grinding noises when you drive, it’s probably the timing belt tensioner. The timing belt can also cause problems with your engine’s valves. When the timing belt is too loose, the valves cannot fully combust the fuel-air mixture. If this problem is left undiagnosed, it could result in severe engine damage. To solve the problem, you must replace the timing belt tensioner.

The repair of the timing belt tensioner is not a difficult job if you’re experienced and comfortable with DIY car repairs. If you have a good knowledge of car repair, you can try to replace it yourself – but don’t forget that it is a complex repair job that requires a lot of skill. So, it’s best to hire a professional mechanic. And if you don’t have the necessary tools and training, you can always try the DIY method.

Other symptoms of a bad timing belt tensioner include an abnormal chirping noise, misfiring, and check engine light malfunction. If you notice any of these symptoms, you should replace the timing belt tensioner as soon as possible. Often, the belt is wearing out and can’t spin freely. You may have to replace the timing belt tensioner to avoid major damage to your engine. The best way to tell if the timing belt tensioner is failing is to check it regularly.

Cost of a new drive belt tensioner

A new drive belt can be expensive. Replacing 1 is usually a straightforward task that requires little knowledge, but some cars are more difficult than others. Replacing a drive belt by yourself may result in the replacement of parts you do not know. You may also encounter problems that cannot be resolved unless you have a mechanic check all the affected parts. You can save money by taking the car to a mechanic before trying to fix the problem yourself.

A drive belt tensioner should last at least 125,000 miles, but can break sooner. Most car mechanics will replace the tensioner after you notice the belt is slipping. It takes about 15 minutes to an hour to replace 1 of these parts, and you can do it yourself with the proper tools. You can also ask about the replacement of pulleys or sprockets. The price of a new drive belt tensioner depends on the make and model of your car.

The average cost to replace a drive belt tensioner is between $235 and $267. This cost includes labor and parts, but doesn’t include taxes or fees. Some vehicles may need related repairs as well, such as serpentine belts or tensioner housing. For a detailed estimate, use the RepairPal Fair Price Estimator. You can compare labor costs and shop for the best price. There are many options available online, and you can choose the most convenient 1 for your needs.

In addition to replacing the drive belt, you should also check the idler pulleys, which do not drive anything. If they have excessive movement, replace them. A failed drive belt tensioner can cause the belt to slip and affect other components of the car. You may also notice warning lights that indicate a problem with the alternator, water pump, or power steering. You should also check your vehicle’s air conditioning.

Replacing the tensioner pulley can be done yourself for about $50. Depending on the type of pulley and belt, you may need to replace other parts of the engine as well. You can save money by replacing a tensioner pulley yourself if you have the time and skills. It’s easy to replace a new drive belt tensioner if you’re a mechanically inclined individual.

Repair options for a failed drive belt tensioner

A failed drive belt tensioner may have several symptoms. For instance, it can make a grinding or squealing sound, and it may emit a burning smell. The battery light on your car may also stay on. These are all signs that your drive belt has failed. However, these symptoms are not always indicative of the failure of the drive belt tensioner. Listed below are some common problems that can be caused by a failed drive belt tensioner.

To check for a failed drive belt tensioner, turn off the engine and examine the arm. If it doesn’t move, it’s time to replace the drive belt. A manual drive belt tensioner is easy to replace. A hydraulic or bad spring drive belt tensioner, however, will not be able to be fixed. If you can’t find a repair shop in your area, visit 1 of NAPA AutoCare locations, or a NAPA online store. They will be able to diagnose the failure and provide solutions for your car.

A spring tensioner is a type of drive belt tensioner that uses a spring-loaded pulley to apply the proper tension to the drive belt. However, spring tensioners can fail and seize if not properly maintained. A hydraulic tensioner uses hydraulic oil under pressure and can malfunction. In some cases, the tensioner can leak oil or lose its ability to tension the drive belt. It can also be damaged by excessive wear, which will cause the belt to break.

A failed drive belt tensioner can affect your car’s performance and functionality. In addition to making your car squeaky and jerky, a failed drive belt tensioner can cause the serpentine or v-belt to slip and wear out prematurely. Repairing a failed drive belt tensioner can also prevent your car from experiencing the same problems in the future. So, what do you do if you find your drive belt is slipping?

If your drive belt tensioner isn’t the problem, you’ll have to replace it. In some cases, a loose tensioner arm can lead to cracks in the tensioner housing. In the worst case scenario, the damaged tensioner can also lead to an overheated engine. Ultimately, a failed drive belt tensioner can cause your car to experience overheating, weak battery charging, and even a weakened power steering system.

Maintenance requirements for a drive belt tensioner

Drive belt tensioner maintenance begins with proper alignment of the pulleys. Misaligned pulleys or drives can wear a belt out too fast. Misalignment can occur if the component was recently replaced. A set of shims can restore the pulleys to the proper alignment. It is important to regularly check the tensioner to ensure proper function. Also, check the belt for cracks or wear.

Before performing any maintenance work, always turn off the drive to protect the motor. The belt should be in a safe position so that it will not fall on the workers. Lock down any moving parts and ensure the fans do not freewheel. When inspecting the drive belt tensioner, examine the belt guard for wear and debris. If the belt is damaged or has excessive heat, it is necessary to clean it or replace it.

It is important to maintain a proper fit between the belt and the drive belt tensioner. An incorrectly-sized drive belt will be difficult to install and adjust. An incorrect-rib count drive belt will fit, but will not last as long. Likewise, drive belts with too many ribs will not last as long. For these reasons, drive belt tensioners should be replaced when they are over 50,000 miles.

A drive belt tensioner is a pulley that rides on the outside surface of the serpentine belt. Its purpose is to maintain constant pressure on the pulleys that power car components. It is typically mounted on the front of the engine, bolted to the crankshaft, and rests against the serpentine belt. If the drive belt is cracked, it needs to be replaced immediately. If the arm is loose or bent, the bearings in the tensioner are probably worn.

The drive belt tensioner is an important part of the drive system, which is essential for smooth operation of the vehicle. However, it does wear out prematurely and should be replaced at a certain mileage. It should also be inspected for normal wear and tear as a result of road dirt, excessive heat, and oil leaks. However, it is important to remember that drive belts are highly sensitive to excessive heat, road dirt, and oil leaks.

China Good quality Infrared Belt Tension Tester U-508 Motor Belt Tension Meter Belt Tensioner with Free Design Custom

Product Description

Infrared Belt Tension Tester AT-180H5 motor belt tension meter Belt tensioner

Brief summary The sonic belt tension meter (U-508) is the handy equipment which enables to measure the tension accurately by analyzing sonic wave without touching.

A sensor catches the produced eruption of sound wave by pick the belt span. After that, the high processing computer analyzes it and shows the result on the screen digitally.

Check points for the immeasurable state [Failed to measure or the results were fluctuated significantly.] ITEM PRESUMED PRESUMED CAUSE CONFIRMATION PONT “Error” shows up or the measure mode can not be engaged or the red light on.

Nothing shows “0” is entered to the unit mass, Check the entered data(Input up or only width & span the correct number)

The frequency displays, but the tension does not measure Change the measurement frequency range measuring Input the wrong frequency range processing sign shows up from the third time of measurin Measured frequency exceeds 5000Hs Battery drain (STHangZhouRD ⇔ HIGH) Check whether the measurement frequency exceeds 5000Hz or not (Frequency mode)

Battery drain The unevenness of the output level is large. The measured value changes The sensor attaches to a belt for Measure again keeping enough a moment distance so that the sensor does not attach to a belt Turn off a power once at the measurement place, then turn it on (Turn on a power with connected the sensor, then push “MEASURE” button after 1 second every time greatly Automatic gain adjustment is not The sensor responds to the background noise keenly enough *Please inquire to us or the dealer where you purchased if the U-508 does not work after checking the points above

U-508 1)Flexible type sensor 3)Two triple A batteries

Sensor outer diameter: 12.5mm

Total length: 170mm 4)Operation manual of U-508 5)Operating procedure sheet for carrying

Measurable frequency band: 10Hz~5000Hz 6)Inspection acceptance certificate 7)Warranty 2)Soft case for carrying 8)Two USB connecting caps (one is for a spare)

Capable of containing the body of tension meter, 9)Operating manual of application software for flexible type sensor etc.

Total length: 170mm U-508 Please use the MINI-B 5 as USB connector

Measurable frequency band: 10Hz~5000Hz

Main Body Power Supply: Two triple A batteries. Alkaline battery is recommended. Mass: 120g Temperature and humidity range for use and storage: -10~-50ºC, 80% (free from condensation) Overall Size: 160(H) × 59(W) × 26(26)

Tips For Replacing a Belt Tensioner

When replacing a serpentine belt or automatic tensioner, you will need a special tool. This tool has a long, flat extension handle that allows you to place a socket onto the bolt and flats on the tensioner arm. The following are some tips to follow when replacing the belt or tensioner on your vehicle. To replace your belt or tensioner, you should start by checking the tensioner’s lubrication.

Serpentine belt

If you notice that the power steering or air conditioning are not working, you should check the serpentine belt tensioner. A malfunctioning serpentine belt tensioner can lead to a host of other issues. The belt may stretch, which can be caused by several factors. Over time, serpentine belt tensioners can also get worn down. Additionally, they can have a variety of other problems, including rust or dirt in the housing.

You can replace your serpentine belt by following the instructions found on your vehicle’s manual. Some tensioners attach to the engine via a single bolt. To remove and replace the belt, remove the old unit and the retaining bolt. Locate the locking pin in the engine and place the new tensioner over it. Use a torque wrench or hand tool to tighten the bolts. When installing the new tensioner, be sure to line up the mounting bolt holes with the mounting bolts. Once the tensioner is installed, test the tension by ensuring that the gauge is above the ribs. If it slides down, it is time to replace the tensioner.

Before you begin the process of replacing your serpentine belt, be sure to park your vehicle in a level area. Turn off the engine and chock both rear wheels before starting the process. Using a diagram from your vehicle’s repair manual can make the process easier, especially if you are a beginner. You can draw it in your hand, or refer to a repair manual to find out the exact location of the tensioner pulley.

If you notice that the belt is slipping or squealing while driving, it may be time to replace the serpentine belt tensioner. A worn-out belt can cause the belt to slip and can cause power steering, air conditioning, and alternator malfunctions. You should also check the belt tensioner regularly. The motor may stall or make a loud noise. These are all signs of worn-out serpentine belt.

A serpentine belt uses less space in the engine than a V-belt. It also provides more tension for the serpentine belt, which prevents it from running hot and squealing. Serpentine belts are manufactured to last for several hundred thousand miles. They are a must-have item for your car! So be sure to keep it maintained and properly adjusted! Then, you can be sure to have your car running smoothly and safely.

If you notice any of these symptoms, you should replace your serpentine belt tensioner. A serpentine belt tensioner is a simple self-10sioning device that is mounted on the front of the engine. These devices are usually easy to replace and are not complicated to install. You can find 1 at any parts store or online. When the time comes to replace your serpentine belt, don’t hesitate to get the parts you need from a local auto part store.

Idler pulley

The idler pulley and the belt tensioner are essential components of your car’s drivetrain. If any 1 of them fails, all of them must be replaced. This is because they were manufactured at the same time and most likely have the same number of miles on them. As a result, they can all fail within a few thousand miles of each other. Here are some of the symptoms that you should look for when inspecting your idler pulley or belt tensioner.

Idler pulleys are a common part of most cars. They play a vital role in the operation of the belt system by directing the belt’s path and providing additional contact with the pulley. The idler pulley is also responsible for turning the cooling fan in an air-cooled Corvair engine. Because of these functions, idler pulleys are often replaced with idlers that differ in size.

Idler pulleys are small, 2 to 4 inches in diameter and mounted on the front of the engine block. Their purpose is to create a constant amount of tension on the drive belt. When the idler pulley is worn out, the accessory drive belt may experience excessive vibration and squealing noises. You may wish to replace it as soon as possible. You can do so at AutoZone.

A worn or damaged idler pulley will require a replacement. The belt itself will not fall off the car unless the idler pulley is damaged. A squealing sound can be a sign of a broken spring. Alternatively, a mechanic can recommend a replacement based on the condition of the idler pulley. In most cases, idler pulleys are more durable than the belts and are therefore recommended for replacement.

You can also notice that the idler pulley is slipping or causing excessive noise. Its constant rotation wears the idler pulley and reduces the tension of the belt. This causes the belt to slip and may even tear off the engine. Ultimately, this could result in stalling. And if you notice the engine belt squealing or making excessive noises, you should consider replacing it.

An idler pulley for a belt tensioner are often confused. Though both of them are used in the same application, they differ in many ways. The tensioner is the 1 that receives pressure from the belts and moves them. The idler pulley is not attached to an adjustable bolt, and it can cause unusual noises. It might even make squealing or odd noises.

Spring tensioner

A spring belt tensioner is a solution to a loose belt. It features a strong torsion spring that reduces slack. These devices are designed to fit up to 6mm wide belts. They are highly reliable and durable. They are also suitable for applications where the engine speed is often fluctuating. Here’s how you can choose the best 1 for your vehicle. The spring in the tensioner should be in the proper position to keep the belt taut and free of slippage.

The RunRight tensioner is a durable, high-quality product that uses aluminum alloy. Its elastomeric inserts rely on highly elastic natural rubber for good shape memory and durability. Spring tensioners are easy to install and maintain. They are designed for both axial and helical drives. They feature detailed technical drawings and 3-D models to help you determine the best 1 for your application. To choose a spring tensioner, visit our website.

A worn bushing in the tensioner pulley or a loose pivot arm can result in excessive noise, vibration, and premature belt failure. In addition, worn springs cannot maintain proper tension. Over time, they lose tension. The pulley arm itself can also become damaged, preventing it from rotating properly. If these problems occur, you’ll need to replace the spring tensioner. If you don’t see any signs of wear, check your mounting bracket and tensioner.

A worn pivot bushing can cause the tensioner arm to misalign, leading to excessive back and forth sway. It may also cause the tensioner to jam, which means the belt is too long or too short. If you notice excessive wobble, you should replace the spring tensioner. A faulty tensioner may also be causing excessive oscillation in the pulley. To determine if the spring tensioner is too weak or jammed, check the belt’s length by using a breaker bar or socket with a long handle ratchet.

When it’s time to replace your serpentine belt, don’t forget to replace the belt tensioner. The tensioner protects other components from premature failure. It is a relatively inexpensive repair. It should be replaced as part of a larger multi-ribbed belt. It also provides protection for other components of the drive system. In addition to its protection and performance, the tensioner is inexpensive and relatively easy to replace.

It’s vital to check the tensioner and idler pulleys to make sure the system is aligned properly. If they don’t align, the belt will slip and cause premature wear. Alternatively, the tensioner may have too much tension, overloading the shaft bearings and causing premature failure in other parts. You should also check the idler pulleys for noise as well, since these are engine-driven accessories.

China Hot selling Timing Belt Pulleys Sheave Industrial Tensioner Taper Bush Zero Backlash Aluminium Cast Iron Motor Conveyor Tractor Flat Bore V Groove Drive V-Belt Pulley with Hot selling

Product Description

Timing Belt Pulley Industrial Tensioner Taper Bush Lock Zero Backlash Aluminium Cast Iron Electric Motor Conveyor Tractor Flat Bore V Groove Drive V-Belt Pulley

V-Belt Pulley:

If You Purchase An Alternator Just About Anywhere, It Will Not Include This Dual V-Belt Pulley Will Not Be Available & Your Must Transfer It From Your Old Alternator.However, If You Need This Pulley And Your Repair Shop Exchanged Your Alternator For A Core & Forgot To Swap It Out, This Is The Cure For Your Problem.This Dual Pulley Is Hard To Come By & Many Years Back & This One Is A Direct Fit For The Full Size Jeeps.This Dual V-Belt Pulley Has A Nice Chrome Finish & Is Made Of Higher Quality Materials For Strength & Durability.

Timing pulley:

Related products:

Company:

Tips For Replacing a Belt Tensioner

When replacing a serpentine belt or automatic tensioner, you will need a special tool. This tool has a long, flat extension handle that allows you to place a socket onto the bolt and flats on the tensioner arm. The following are some tips to follow when replacing the belt or tensioner on your vehicle. To replace your belt or tensioner, you should start by checking the tensioner’s lubrication.

Serpentine belt

If you notice that the power steering or air conditioning are not working, you should check the serpentine belt tensioner. A malfunctioning serpentine belt tensioner can lead to a host of other issues. The belt may stretch, which can be caused by several factors. Over time, serpentine belt tensioners can also get worn down. Additionally, they can have a variety of other problems, including rust or dirt in the housing.

You can replace your serpentine belt by following the instructions found on your vehicle’s manual. Some tensioners attach to the engine via a single bolt. To remove and replace the belt, remove the old unit and the retaining bolt. Locate the locking pin in the engine and place the new tensioner over it. Use a torque wrench or hand tool to tighten the bolts. When installing the new tensioner, be sure to line up the mounting bolt holes with the mounting bolts. Once the tensioner is installed, test the tension by ensuring that the gauge is above the ribs. If it slides down, it is time to replace the tensioner.

Before you begin the process of replacing your serpentine belt, be sure to park your vehicle in a level area. Turn off the engine and chock both rear wheels before starting the process. Using a diagram from your vehicle’s repair manual can make the process easier, especially if you are a beginner. You can draw it in your hand, or refer to a repair manual to find out the exact location of the tensioner pulley.

If you notice that the belt is slipping or squealing while driving, it may be time to replace the serpentine belt tensioner. A worn-out belt can cause the belt to slip and can cause power steering, air conditioning, and alternator malfunctions. You should also check the belt tensioner regularly. The motor may stall or make a loud noise. These are all signs of worn-out serpentine belt.

A serpentine belt uses less space in the engine than a V-belt. It also provides more tension for the serpentine belt, which prevents it from running hot and squealing. Serpentine belts are manufactured to last for several hundred thousand miles. They are a must-have item for your car! So be sure to keep it maintained and properly adjusted! Then, you can be sure to have your car running smoothly and safely.

If you notice any of these symptoms, you should replace your serpentine belt tensioner. A serpentine belt tensioner is a simple self-10sioning device that is mounted on the front of the engine. These devices are usually easy to replace and are not complicated to install. You can find 1 at any parts store or online. When the time comes to replace your serpentine belt, don’t hesitate to get the parts you need from a local auto part store.

Idler pulley

The idler pulley and the belt tensioner are essential components of your car’s drivetrain. If any 1 of them fails, all of them must be replaced. This is because they were manufactured at the same time and most likely have the same number of miles on them. As a result, they can all fail within a few thousand miles of each other. Here are some of the symptoms that you should look for when inspecting your idler pulley or belt tensioner.

Idler pulleys are a common part of most cars. They play a vital role in the operation of the belt system by directing the belt’s path and providing additional contact with the pulley. The idler pulley is also responsible for turning the cooling fan in an air-cooled Corvair engine. Because of these functions, idler pulleys are often replaced with idlers that differ in size.

Idler pulleys are small, 2 to 4 inches in diameter and mounted on the front of the engine block. Their purpose is to create a constant amount of tension on the drive belt. When the idler pulley is worn out, the accessory drive belt may experience excessive vibration and squealing noises. You may wish to replace it as soon as possible. You can do so at AutoZone.

A worn or damaged idler pulley will require a replacement. The belt itself will not fall off the car unless the idler pulley is damaged. A squealing sound can be a sign of a broken spring. Alternatively, a mechanic can recommend a replacement based on the condition of the idler pulley. In most cases, idler pulleys are more durable than the belts and are therefore recommended for replacement.

You can also notice that the idler pulley is slipping or causing excessive noise. Its constant rotation wears the idler pulley and reduces the tension of the belt. This causes the belt to slip and may even tear off the engine. Ultimately, this could result in stalling. And if you notice the engine belt squealing or making excessive noises, you should consider replacing it.

An idler pulley for a belt tensioner are often confused. Though both of them are used in the same application, they differ in many ways. The tensioner is the 1 that receives pressure from the belts and moves them. The idler pulley is not attached to an adjustable bolt, and it can cause unusual noises. It might even make squealing or odd noises.

Spring tensioner

A spring belt tensioner is a solution to a loose belt. It features a strong torsion spring that reduces slack. These devices are designed to fit up to 6mm wide belts. They are highly reliable and durable. They are also suitable for applications where the engine speed is often fluctuating. Here’s how you can choose the best 1 for your vehicle. The spring in the tensioner should be in the proper position to keep the belt taut and free of slippage.

The RunRight tensioner is a durable, high-quality product that uses aluminum alloy. Its elastomeric inserts rely on highly elastic natural rubber for good shape memory and durability. Spring tensioners are easy to install and maintain. They are designed for both axial and helical drives. They feature detailed technical drawings and 3-D models to help you determine the best 1 for your application. To choose a spring tensioner, visit our website.

A worn bushing in the tensioner pulley or a loose pivot arm can result in excessive noise, vibration, and premature belt failure. In addition, worn springs cannot maintain proper tension. Over time, they lose tension. The pulley arm itself can also become damaged, preventing it from rotating properly. If these problems occur, you’ll need to replace the spring tensioner. If you don’t see any signs of wear, check your mounting bracket and tensioner.

A worn pivot bushing can cause the tensioner arm to misalign, leading to excessive back and forth sway. It may also cause the tensioner to jam, which means the belt is too long or too short. If you notice excessive wobble, you should replace the spring tensioner. A faulty tensioner may also be causing excessive oscillation in the pulley. To determine if the spring tensioner is too weak or jammed, check the belt’s length by using a breaker bar or socket with a long handle ratchet.

When it’s time to replace your serpentine belt, don’t forget to replace the belt tensioner. The tensioner protects other components from premature failure. It is a relatively inexpensive repair. It should be replaced as part of a larger multi-ribbed belt. It also provides protection for other components of the drive system. In addition to its protection and performance, the tensioner is inexpensive and relatively easy to replace.

It’s vital to check the tensioner and idler pulleys to make sure the system is aligned properly. If they don’t align, the belt will slip and cause premature wear. Alternatively, the tensioner may have too much tension, overloading the shaft bearings and causing premature failure in other parts. You should also check the idler pulleys for noise as well, since these are engine-driven accessories.

China wholesaler Motorcycle Spark Plug for CZPT Motor Saluto 125cc with high quality

Product Description

Model Number:CPR7EA-9———————–Type:Moto Normal Spark Plug

Place of Origin:HangZhou, China———————–Brand Name:KGV

Reach:19mm—————————————-Thread:M10x1.25

Hex:16mm——————————————–Electrode Type:Normal

Resistor or Non-Resistor:Resistor—-====–Color:White

Auto Spark Plug:ignition parts———————Life time:50000km

Carton size:200pcs in 1 carton————–Warranty:30000 Kilometers

Car Make:Oem Car——————————–OE NO.:N/A

Model Recommendation List: Saluto 125cc

1.Ground electrode with platinum tip

Platinum raw materials, has good thermal conductive performance.

Special laser processing and point to point patterns, make ignition

more easily and substantially increase the working life time.

2.All-round laser welding

Iridium raw materials, the melting point of 2454 Celsius

degrees Combinations of resistance and laser welding tech

process.

3.All-round laser welding

Features of Iridium Spark Plug

Improve Ignitability & Fuel Econom

Ignite Status:

Comparing with Normal Spark Plug ,the flame of Iridium spark plug spread more frequenty. Iridium spark plug improve much more the ignitability and fuel economy

Improve Acceleration

Improve Acceleration:

With the 0.5mm center electrode, the accelerating performance improves obviously. The time difference to speed up would be shortened 0.7 to 1 second.

Improve Engine Staring

Improve Engine Starting:

With the powerful ignitability, the Iridium spark plug can ignite the engine easily and make less cut off even under thin air and adverse environment.

Normal Spark Plug

1.Electrode Material:Center electrode: Nickel; Ground electrode: Nickel

2.Feature:Most of the original car use this spark plug

3.Lifetime:The designed life is 5 W KM; The best economic life is 3 W KM

4.Advantage:Lower cost

Platinum Spark Plug

1.Electrode Material:Center electrode:Platinum; Ground electrode: Nickel

2.Feature:Cost-effective high performance

3.Lifetime:The designed life is 7 W KM; The best economic life is 5 W KM

4.Advantage:Start easy; Accelerated fast

Iridium Spark Plug

1.Electrode Material:Center electrode: Iridium; Ground electrode: Nickel

2.Feature:Start easy;Fuel saving;Accelerated fast Combustion

3.Lifetime:The designed life is 8 W KM; The best economic life is 6 W KM

4.Advantage:Start easy;Fuel saving;Accelerated fast Combustion

Iridium/Platinum Spark Plug

1.Electrode Material:Center electrode:Iridium; Ground electrode:Nickel

2.Feature:Start easy;Fuel saving;Accelerated fast Combustion

3.Lifetime:The designed life is 16 W KM; The best economic life is 8 W KM

4.Advantage:Start easy;Fuel saving;Accelerated fast Combustion;Longer lifetime

Double Iridium Spark Plug

1.Electrode Material:Center electrode: Iridium; Ground electrode: Iridium

2.Feature:The fastest accelerating

3.Lifetime:The designed life is 16 W KM;The best economic life is 8 W KM

4.Advantage:Start fast;Power upgrade;Stable ignition;Lowest misfire;Complete combustion;Fuel saving;Clean the exhaust Longest Lifetime

1.HangZhou INDUSTRIAL & TRADING DEVELOPING CO., LTD.was established in 2002 in china.

2.Our company is a professional manufacturer of Spark Plugs .

3.We can provide many kind of spark plug:

- CNG/LPG Spark Plug

- Motorcycle Spark Plug

- Auto Spark Plug

- Small Engine Spark Plug

4.We have a complete range of product,including spark plug ,filter,brake pads etc.

5.Cooperate with many OEM clients such as Lifan,Sanlg,Suzuki,Wangye Qipa etc.

FAQ

Q1:What’s the minimum order quantity for the first purchasing?

A1:Generally speaking normal Spark Plug 5000PCS(total amount reaches 20000PCS), iridium Spark Plug 1000PCS/each model( (unlimited).For further information,please contact us.

Q2:How can we get to know the quality before placing an order?

A2:Samples are provided for quality test.

Q3:How can we get samples from you?

A3:Free samples are provided,you just to need take care of the freight by below three ways.

***Offering us the courier account

***Arranging pick-up service

***Paying the freight to us by bank transfer.

Q4:What’s loading capacity for 20ft container?

A4:Max loading capacity is 22tons,exact loading capacity depends on the spark plug model you choose and the country you come from.For further information,please contact us.

Q5:How long is the delivery time?

A5:30-35 days after received the deposit.If you have special requirement on delivery time,

please let us know.

Q6:What’s the payment terms?

A6:Normally Bank transfer or other as your request.

Q7:What should we do if quality defects occurred after received the goods?

A7:Please kindly send us photos with detailed description by email,we will solve it for you immediately,refund or exchange will be arranged once verified.

Q8:Is it possible to load mix-products in one container?

A8:Yes,it’s available.

Our Service

HangZhou INDUSTRIAL & TRADING DEVELOPING CO., LTD.

1.HangZhou INDUSTRIAL & TRADING DEVELOPING CO., LTD.was established in 2002 in china.

2.Our company is a professional manufacturer of Spark Plugs .

3.We can provide many kind of spark plug:

- CNG/LPG Spark Plug

- Motorcycle Spark Plug

- Auto Spark Plug

- Small Engine Spark Plug

- Genrator Spark Plug

4.We have a complete range of product,including spark plug ,filter,brake pads etc.

5.Cooperate with many OEM clients such as Lifan,Sanlg,Suzuki,Wangye Qipa etc.6. Offer quality product with competitive price.

7. Comprehensive service for order following and tracking.

8. OEM and customize design for your potential marketing product.

9. Friendly service and prompt reply within 24 hours.

What Is a V-Belt?

A v-belt is a type of belt that provides a continuous motion to the vehicle’s wheels. This type of belt is made of several different components. They usually have a trapezium-shaped cross-section because of its elastomer core. Elastomers are often made of polyurethane or a synthetic rubber with good shock resistance. Sometimes, a v-belt will have 2 sections – cushion rubber and compression rubber.

Link-type V-belt

A laminated link-type V-belt is 1 embodiment of the present invention. The belt comprises individual lamina sections connected longitudinally by studs and tubes, each of which has at least 1 connecting means. The slots in the links allow for a full share of the load to be transferred through the belt, and they also reduce substantially all internal mechanical stresses. The belt is preferably designed to extend substantially the entire width of the machine being driven.

Conventional link-type V-belts are installed between 2 pulleys on the tight side of the V-drive. A wide end of a link moves in the direction of rotation, while the stud of a second, smaller link pulls the nose end of the third link forward. The shank of the stud pivots on a solid fabric located in hole 2 of the third link below. The bottom link, however, curls over the stud and the belt is assembled.

The present invention offers an improved method of forming a link-type V-belt. The belt is manufactured using links and does not have to be fitted as tightly as conventional link-type V-belts. This belt is flexible and strong enough to handle normal tension loads in a well-designed drive. In addition, the belts made using the present invention will have a longer life, thereby extending the drive’s load-carrying capacity.

Classical V-belt

A classical trapezoidal belt profile makes the VB Classical V-belt ideal for various industrial applications. Available in small sizes from 5mm to 3mm, these belts are available with cogged or raw edges. Their highly engineered construction makes them ideal for a variety of uses. These belts are commonly used in motors, compressors, milling machines, mixers, and other mechanical devices. To determine the right belt for your application, consider the following factors.

The classic v-belt is the most common and economically-priced type of v-belt. They are manufactured using special formulated rubber reinforced with polyester cords. These belts can span from 16 inches to 400 inches in length. The classic V-belt is also very easy to replace. The belt’s outer diameter and pitch can be measured. The length is typically standardized by the Association for Rubber Product Manufacturers.

Typically, classical V-belts are used in single-belt drives. Because they don’t require lubrication or maintenance, these belts are often available in sizes A and B. However, larger belt sizes are rarely used for single-belt drives. In such cases, multiple A or B belts are an economical alternative to single-belt C. In addition, narrower-profile V-belts provide higher power ratings than conventional V-belts because of their higher depth-to-width ratio. These belts are ideal for heavy-duty applications.

Narrow V-belt

The narrow v-belt is the same as a conventional v-belt, but it has a smaller top and bottom width. This makes it suitable for higher horsepower applications, and it is used in high-end sports cars. Narrow v-belts are generally characterized by a letter “v” on the top side and a length of outside dimensions of 1.6:1.

The steel wires that comprise the core of the v-belt are endless and are free of joints. This provides the strength required for torque transmission. A base rubber compound is placed around the steel wire and acts as a medium of compression and shock absorption during power transmission. A plastic layer acts as a protective cover, and provides the rubber with a degree of temperature tolerance. While choosing a narrow v-belt, it is important to keep in mind that there are some disadvantages to a narrow V-belt.

For example, a narrow V-belt is suitable for high-power applications, and may be used in a small assembly space. Its narrow profile also allows it to be space-saving in layout and allows high-speed drives without additional belts. Furthermore, it reduces operating and maintenance costs. It is ideal for applications where space is limited, and a high torque is required. The benefits of a narrow V-belt are plentiful.

Banded belt

Identifying a banded v-belt can be tricky, but there are a few signs that can indicate a possible problem. Cracked belts can be difficult to spot, but they can be an early indicator of a more serious problem. Look for cracked underside edges, worn covers, and misplaced slack. If 1 or more of these factors applies to your belt, you may want to seek a replacement.

Banded v-belts are made with an elastomer core. The main component of this belt is the elastomer, which is used for the band’s flexural strength and shock resistance. It’s sometimes separated into 2 sections, with each section connected to the other by a tension cord. This gives the belt its trapezium cross-section, which increases tensile strength.

The 2 main types of banded v-belts are wrapped or raw edge. Wrapped v-belts have a fiber-covered body while raw edge belts are uncovered. Banded v-belts are often classified by their cross-section, and include: standard v-belt, wedge v-belt, narrow versus double v-belt, cogged v-belt, and double t-belt.

Banded v-belts are popular with commercial applications. Whether you’re looking for a 2V-belt or a large 8V-belt, V-Belt Guys has what you need. We also stock a wide variety of different banded v-belts and can help you find 1 that fits your needs and budget. Take a look at our selection today!

Traditional V-belt

Although a traditional V-belt may be a glorified rubber band, modern variations reflect advances in engineering. Proper installation and maintenance are essential for trouble-free service. When you are replacing a traditional V-belt, be sure to follow these simple steps to ensure its longevity. Read on to learn more. Listed below are the features of each type of V-belt. Identify the type of belt you need by measuring its top width, circumference, and dimensions.

TEC Traditional V-belts have an exceptionally low slip rate and are resistant to high operating temperatures. These types of belts do not experience early belt aging. They are also highly resistant to poor operating conditions. However, the maintenance is more extensive than other types of belts. A typical V-belt part number is B50, which is the cross-section size of a 50-inch belt. The belt’s lifespan is greatly increased because of this feature.

A ribbed V-belt is another option. It has a deeper V than a traditional V-belt. The ribs in this type are narrower and more flexible. These ribs are smaller than the classic V-belt, but they can transmit 3 times as much horsepower. Because they are thinner, these belts are more flexible than traditional V-belts. The thickness of the ribs is less critical.

Metric V-belt

Metric V-belts are made to a more precise standard than their American counterparts. These belts are manufactured to meet ARPM tolerances, making them suitable for industrial, machine, and food processing applications. This metric system is also more convenient than converting between the 2 units. Listed below are the most common uses for a Metric V-belt. If you’re in the market for a new belt, consider ordering a metric one.Metric V-belts are made to a more precise standard than their American counterparts. These belts are manufactured to meet ARPM tolerances, making them suitable for industrial, machine, and food processing applications. This metric system is also more convenient than converting between the 2 units. Listed below are the most common uses for a Metric V-belt. If you’re in the market for a new belt, consider ordering a metric one.

Metric V-belts are generally more durable than their equivalents made of standard American-sized belts. Metric V-belts are available in many different sizes to fit different machineries. In addition to offering superior load-carrying capacity, Metric Power(tm) V-belts are known for their exceptional flex and stretch characteristics. For optimum performance in textile mills, food processing, and machine tool applications, Metric Power(tm) V-belts are manufactured using a proprietary construction that combines a higher load-carrying capacity with superior flex and stretch.

Metric belts can generate 50% to 100% more horsepower than conventional and classic sectioned belts. This is achieved through improved construction and placement of the cord line. These belts also have unique wedge designs that help them support the cord in motion. However, you must ensure the proper tension when buying a Metric V-belt, because improper tension may damage the belt. They are compatible with both U.S. and international standards.

China Best Sales CZPT MTA11 QSM diesel engine motor parts 3062602 idler pulley near me manufacturer

Product Description

CZPT MTA11 QSM diesel engine motor parts 3062602 idler pulley,; with list of idler belt tensioner pulleys for CZPT engines,; as below:;

| Model | Description | Part Number | Part Number | Part Number | Part Number | Part Number |

| 4BT | belt tensioner | 3922900 | 3914854 | 3936210 | 3936198 | 3936207 |

| 4BT 6BT | belt tensioner | 3936204 | 3937555 | 3936197 | 3936206 | 3936201 |

| 6BT | belt tensioner | 3937553 | 3934818 | 3914086 | 3978571 | 3936202 |

| 6BT 6CT | belt tensioner | 3936203 | 3924026 | 3978571 | 4994573 | 3976832 |

| 6BT | belt tensioner | 3928748 | 3934824 | 3936208 | 3973825 | 3976832 |

| 6BT | belt tensioner | 5333478 | ||||

| 6BT 6CT | belt tensioner | 3937556 | 4898548 | 4987964 | 3936212 | 3934830 |

| 6CT | belt tensioner | 3969564 | 3959042 | 3991495 | 3936213 | 3976831 |

| 6ISBE/6LT | belt tensioner | 3947574 | 4891116 | 4936640 | 4987964 | 3979316 |

| ISF2.;8 | belt tensioner | 5262500 | ||||

| ISF3.;8 | belt tensioner | 5267127 | 5287571 | 4980639 | 5287571 | |

| KTA19 | belt tensioner | 3009639 | ||||

| MTA11 | belt tensioner | 3457141 | 3400885 | 3157189 | 3062602 | |

| ISF2.;8 | Chain and guide | 4982040 | 5267973 | 5262516 | 5259767 |

manufactured by joint venture of US CZPT in China.; We also sell other CZPT models,; including 4BT3.;9,; 6BT5.;9,; 6CT8.;3,; 6LT8.;9,; ISZ13,; M11,; NT855,; KT19,; KT38,; KT50,; 4ISBE4.;5,; 6ISBE6.;7,; ISLe8.;9,; ISF2.;8,; ISF3.;8,; ISMe11,; etc,; for stationary generator set,; water pump set,; fire pump set,; construction and engineering machinery (road roller,; wheel loader,; excavator,; bulldozer,; forklift,; hoister,; trailer,; etc);,; automobile (bus,; coach,; van,; MPV,; SUV,; pick-up,; etc);,; marine main propulsion,; marine auxiliary generator set,; etc.;

What Is a V-Belt?

What is a v-belt? It is a rubber belt that is trapezium-shaped and has an elastomer core that holds the parts together. Its elastomer core is generally made of polyurethane and has good shock resistance and flexural strength. V-belts sometimes have 2 sections, 1 of which is a compression rubber and the other cushion rubber. They can be narrow or wide, depending on their use.

Classical V-belts replace leather belts

Classical V-belts are a popular choice among truck drivers because they are more durable. They are typically made of polymer or rubber, with fibers from other materials added for reinforcement. These belts are a good replacement for leather belts and offer many benefits. They are durable, offer excellent temperature and oil resistance, and are easy to use. If you’re considering replacing your current belt, consider buying a replacement belt made of the same material.

Most classical V-belts are used individually and come in A and B sizes. They are rarely used in single-belt drives. Buying several A or B belts instead of 1 C belt can save money. The narrow V-belts also provide higher power ratings. This is due to their narrow profile, which places more of the reinforcing cord under the sheave. Narrow V-belts are ideal for heavy duty applications.

When you’re replacing an existing V-belt, you’ll need to measure its top width and circumference. Once you’ve determined these parameters, you’ll be able to select the right replacement belt. Make sure to take measurements of the belt’s dimensions and top width before ordering. Using these measurements will help you determine the best size for your new belt. You’ll be able to tell whether you need a larger or smaller belt after measuring the top width and circumference.

If you’re looking to replace your leather belt with a belt made of synthetic material, a Classical V-belt may be the right choice. Classical V-belts are available in many materials and are more durable than leather. And because they are so versatile, they are the perfect replacement for your current belts. You’ll be glad you did. So, don’t be afraid to experiment with this type of belt. They’ll work well in any setting, including heavy equipment.

When buying a Classical V-belt, be sure to check the dimensions and type of belt you choose. These are available in notched or cogged designs. Notches are a great way to reduce bending stress. Notches also help dissipate heat from the belt, a major factor in premature belt failure. Notched V-belts are designed to balance a combination of flexibility and tensile cord support. They are spaced properly to minimize cracking and undercord damage.