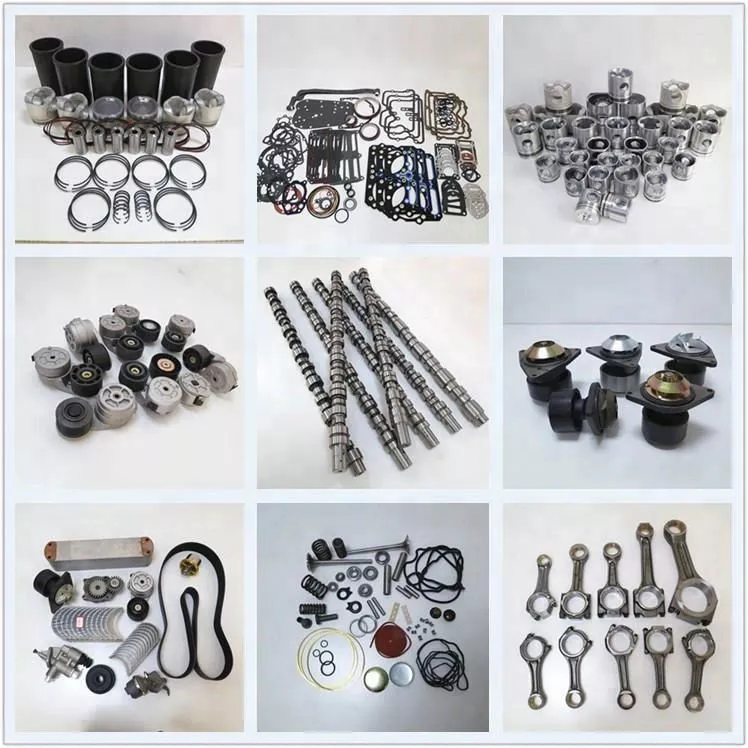

Product Description

Detailed Photos

Our goal is to provide high-quality, modern design, reasonable prices, and good after-sales product services

Company Profile

Factory View

FAQ

| 1- If you are interested in purchasing products,please contact our responsible person,online or telephone communication

Most friends contact our responsible person to inquire: 2-About the price The price in the information is our company’s approximate wholesale price, 3-About delivery We will confirm the way of cooperation and cooperation reached for you to 4-About cooperation We are in line with the production of excellence, CZPT and trustworthy busi- 5- how can we guarantee quality? Always a pre-production sample before mass production; |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 12 Months |

|---|---|

| Warranty: | 12 Months |

| Type: | Variable Timing Wheel |

| Certification: | TUV |

| Applicable: | Truck, Car, Machinery |

| Quality: | Top |

| Customization: |

Available

| Customized Request |

|---|

Can you explain the benefits of using belt tensioners in preventing slippage and optimizing power transmission in machinery?

Using belt tensioners in machinery offers several benefits in preventing slippage and optimizing power transmission. Belt tensioners play a critical role in maintaining proper tension in the belt, ensuring efficient power transfer, and preventing slippage that can lead to decreased performance and premature wear. Here’s a detailed explanation of the benefits:

- Slippage Prevention:

- Efficient Power Transmission:

- Load Handling:

- Reduced Wear and Maintenance:

- System Reliability:

- Noise and Vibration Reduction:

Belt tensioners are primarily designed to prevent slippage between the belt and the pulleys. Slippage occurs when the belt loses traction with the pulleys, resulting in a loss of power transmission efficiency. Belt tensioners apply sufficient force to keep the belt tightly engaged with the pulleys, minimizing the risk of slippage. By maintaining the appropriate tension, tensioners ensure a reliable grip between the belt and the pulleys, preventing power loss, and maintaining optimal performance.

Proper tension provided by belt tensioners is crucial for efficient power transmission in machinery. When the belt is properly tensioned, it remains securely engaged with the pulleys, allowing for efficient transfer of power. The tensioner ensures that the belt maintains the necessary grip and traction to transmit power effectively, minimizing energy losses associated with slippage. By optimizing power transmission, belt tensioners contribute to improved overall system efficiency and performance.

Belt tensioners help in handling varying loads in machinery. As loads fluctuate, the tension in the belt needs to be adjusted to accommodate the changes. Belt tensioners with adjustable features allow for fine-tuning of the tension, ensuring that the belt remains properly tensioned under different load conditions. This flexibility helps optimize power transmission and prevents slippage, even when the machinery is subjected to varying loads, resulting in reliable and consistent performance.

Slippage between the belt and the pulleys can cause accelerated wear on both components. Belt tensioners mitigate slippage, reducing the frictional forces that lead to excessive wear. By maintaining proper tension, tensioners distribute the load evenly across the belt, minimizing localized wear. This results in reduced belt wear, extending the lifespan of both the belt and the pulleys. Additionally, by preventing slippage, belt tensioners help reduce the need for frequent belt replacements and adjustments, resulting in reduced maintenance requirements and costs.

Using belt tensioners improves the overall reliability of machinery. By preventing slippage and maintaining optimal power transmission, tensioners help ensure the consistent performance of belt-driven systems. This reduces the risk of unexpected power losses, interruptions in operation, or damage to other system components. Belt tensioners contribute to the overall reliability and uptime of the machinery, enhancing productivity and reducing the potential for costly downtime.

Slippage between the belt and the pulleys can generate noise and vibrations in machinery. Belt tensioners help minimize these issues by maintaining proper tension and preventing slippage. By ensuring a secure grip between the belt and the pulleys, tensioners reduce the likelihood of belt resonance, belt flutter, or excessive vibrations. This results in quieter operation and improved comfort for operators or users of the machinery.

In summary, using belt tensioners in machinery offers several benefits in preventing slippage and optimizing power transmission. By maintaining proper tension, tensioners prevent slippage, ensure efficient power transfer, handle varying loads, reduce wear and maintenance needs, enhance system reliability, and minimize noise and vibrations. Incorporating belt tensioners into machinery design helps maximize performance, extend component lifespan, and ensure reliable operation in various industrial applications.

How do innovations and advancements in belt tensioner technology impact their use?

Innovations and advancements in belt tensioner technology have a significant impact on their use, enhancing performance, reliability, and versatility. These advancements introduce new features, improve functionality, and address specific challenges associated with belt-driven systems. Here’s a detailed explanation of how innovations and advancements in belt tensioner technology impact their use:

- Improved Tensioning Mechanisms:

- Enhanced Durability:

- Increased Compatibility:

- Noise and Vibration Reduction:

- Advanced Monitoring and Diagnostic Capabilities:

- Integration with System Controls:

New tensioning mechanisms and designs have been developed to provide more precise and efficient tension control. Innovations such as automatic tensioners or self-adjusting tensioners utilize advanced mechanisms that can continuously monitor and adjust the tension in real-time. This improves the overall performance and reliability of belt-driven systems, as the tension can be accurately maintained even under varying loads and operating conditions.

Advancements in materials and manufacturing techniques have contributed to the development of more durable belt tensioners. High-strength alloys, advanced polymers, and specialized coatings are used to increase the resistance to wear, corrosion, and fatigue. These improvements extend the service life of belt tensioners, reducing the frequency of maintenance and replacement and improving the overall reliability of belt-driven systems.

Innovations in belt tensioner technology have led to increased compatibility with a wide range of belt drive systems. Manufacturers have developed adjustable tensioners that can accommodate different belt widths, profiles, and types. This versatility allows for easier integration and replacement of tensioners in various industrial or automotive applications, reducing the need for custom solutions and simplifying maintenance and repairs.

New technologies and designs have been introduced to minimize noise and vibration generated by belt tensioners. Innovative damping materials, improved bearing systems, and optimized geometries help reduce noise and vibration levels, resulting in quieter and smoother operation. This is particularly beneficial in applications where noise reduction and operator comfort are essential.

Advancements in belt tensioner technology have facilitated the integration of monitoring and diagnostic capabilities. Smart tensioners equipped with sensors and connectivity features can provide real-time data on tension levels, temperature, and other operating parameters. This enables predictive maintenance, early fault detection, and optimized performance. By leveraging data-driven insights, operators can make informed decisions, improve system efficiency, and prevent unexpected failures.

Innovative belt tensioner technologies can be integrated with system controls and automation platforms. This allows for seamless integration into larger control systems, enabling automated tension adjustments, synchronization with other components, and coordinated operation. The integration of belt tensioners with system controls enhances system performance, efficiency, and overall productivity.

In summary, innovations and advancements in belt tensioner technology have a significant impact on their use. These advancements improve tensioning mechanisms, enhance durability, increase compatibility, reduce noise and vibration, enable advanced monitoring and diagnostics, and facilitate integration with system controls. By incorporating these innovations, belt tensioners offer improved performance, reliability, and versatility, leading to enhanced efficiency and reduced maintenance requirements in various industrial and automotive applications.

Can you describe the various types of belt tensioners, such as automatic or manual tensioners?

There are various types of belt tensioners available, each designed to fulfill specific requirements in maintaining belt tension. Here’s a description of the different types of belt tensioners:

- Manual Belt Tensioners:

- Automatic Belt Tensioners:

- Hydraulic Belt Tensioners:

- Eccentric Belt Tensioners:

- Idler Pulley Tensioners:

Manual belt tensioners are the most basic type and require manual adjustment to set and maintain the desired tension. They typically consist of an adjustable arm or bracket that can be moved to increase or decrease the tension in the belt. Manual tensioners are commonly used in applications where tension adjustments are infrequent or can be easily accessed for manual adjustment. They are simple, cost-effective, and widely used in various industries.

Automatic belt tensioners, also known as self-adjusting or spring-loaded tensioners, are designed to maintain the proper tension automatically. They incorporate a spring mechanism that applies constant tension to the belt, compensating for belt elongation and wear over time. Automatic tensioners are commonly used in applications where frequent manual adjustments are impractical or where consistent tension control is essential. They provide convenience, minimize maintenance requirements, and ensure optimal tension without the need for manual intervention.

Hydraulic belt tensioners utilize hydraulic pressure to maintain belt tension. They consist of a hydraulic cylinder or piston that applies force to the tensioner arm, adjusting the tension in the belt. Hydraulic tensioners are commonly used in applications with high load requirements or variable operating conditions. They provide precise tension control, can compensate for changes in temperature and load, and are often employed in heavy-duty industrial machinery and automotive applications.

Eccentric belt tensioners use an eccentric mechanism to adjust the tension in the belt. They typically feature an eccentric pulley or roller that can be rotated to increase or decrease the tension. Eccentric tensioners are commonly used in applications where precise tension adjustments are required, such as high-performance engines or systems with specific belt tension specifications. They offer fine-tuning capabilities and are often found in automotive racing, performance tuning, and specialized machinery.

Idler pulley tensioners, also known as fixed tensioners or idler pulley assemblies, are a type of belt tensioner that utilizes an idler pulley to maintain tension. They are typically positioned on the slack side of the belt, providing guidance and tension control. Idler pulley tensioners are commonly used in applications where a fixed tension is desired, and the tensioning capability is provided by other components in the system, such as an automatic tensioner or an adjustable drive pulley.

In addition to these types, there are also specialized belt tensioners designed for specific applications or industries, such as torsional vibration dampers used in automotive engines to reduce vibrations, or belt tensioners with built-in dampening mechanisms to minimize noise in certain applications.

Overall, the choice of belt tensioner depends on factors such as the application requirements, load conditions, frequency of tension adjustments, and the desired level of automation and control. Selecting the appropriate type of belt tensioner is crucial to maintaining optimal belt tension and ensuring the efficient and reliable operation of belt-driven systems.

editor by CX 2024-04-13

China high quality Auto Spare Parts Car Bearing Timing Belt Tensioner Pulley for CZPT A1 A3 A5 V5 OEM 473h-1007060 broken axle on car

Product Description

Product Description

Product name: Auto Spare Parts Car Bearing Timing Belt Tensioner Pulley For Chery A1 A3 A5 V5 OEM 473H-10571

OEM Number:473H-10571

Application: For Chery A1 A3 A5 V5

Package: Original genuine packing, Brand packing, Neutral packing with parts number label

MOQ:1 PC

Delivery time:1-7days

Place: HangZhou China

TIPS: The adaptation of parts is very complex, you need to provide chassis VIN number or car details {model, capacity, year of production (not buy) year} to customer service, and according to the customer service recommend to choose the appropriate type.

Detailed Photos

Packaging & Shipping

Shipping by Sea: containers goods,

Sample order by air: China Post, Ali-express standard shipping, E-pocket, EMS,UPS,TNT,DHL,Fedex, etc

Company Profile

Our Advantages

1. One-stop service to supply all jac motors spare parts (JAC motors j2 j3 j4 j5 j6, s2 /T40,s3/ T5 ,s5/ T6 ,JAC refine ,JAC sunray ,JAC pickup T6 T8,JAC Truck … )

SAIC MG, Maxus Parts, CZPT spare parts

Chery, Changan, BYD, CZPT GWM, Brillance, Geely, Xihu (West Lake) Dis.feng spare parts

Mercedes Benz Parts,

Gates Auto Parts, Phc Parts

2. MOQ: 1PC

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every 2 days, until you get the products. When you got the goods, and give us a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral boxes, original OE cartons or brands AQBP packages

Q2. How to do the order if your need parts have not in this shop?

A: If in this shop has no the parts you need, please tell us, and we will find it from our big warehouse, take photos and send price to you.

Q3. How much you should pay money if buy some items together?

A: After buying some items together, there will be different shipping fees and different goods price, so we can discuss how to do the best shipping way.

Q4. How about your delivery time?

A: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends on shipping way and different countries.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Tensioner Bearing |

|---|---|

| Material: | Metal |

| Car Make: | Chery |

| Fitment: | Chery |

| Model: | A5 |

| Year: | 2004- |

| Customization: |

Available

| Customized Request |

|---|

Can you provide guidance on the selection and sizing of belt tensioners for specific belt applications?

When selecting and sizing belt tensioners for specific belt applications, several factors need to be considered to ensure optimal performance and longevity. Here’s a detailed guidance on the selection and sizing of belt tensioners:

- Belt Type and Size:

- System Requirements:

- Tensioner Type:

- Tensioner Design and Mounting:

- Tensioner Load Capacity:

- Environmental Considerations:

- Manufacturer Recommendations:

Start by identifying the type and size of the belt used in the application. Belts can vary in terms of width, length, profile (V-belt, timing belt, etc.), and construction material (rubber, polyurethane, etc.). The tensioner should be compatible with the specific belt type and size to ensure proper fit and functionality.

Consider the requirements of the belt-driven system. Evaluate factors such as the desired tension level, operating speed, load conditions, and environmental factors. The tensioner should be capable of providing the required tension force while accommodating the system’s operating parameters.

Choose the appropriate tensioner type based on the application’s needs. Common types include automatic tensioners, idler pulley tensioners, spring-loaded tensioners, and hydraulic tensioners. Each type has its advantages and limitations, so select the one that best suits the specific belt application.

Consider the design and mounting requirements of the tensioner. Evaluate the space availability, mounting configuration, and alignment with other components in the belt drive system. Some tensioners offer adjustable mounting positions or different design variations to accommodate various installation scenarios.

Check the load capacity of the tensioner to ensure it can handle the expected loads and forces in the belt system. Consider factors such as the belt tension, shock loads, and dynamic forces. The tensioner should have adequate load capacity to prevent premature wear or failure under normal operating conditions.

Assess the environmental conditions in which the tensioner will operate. Factors such as temperature extremes, moisture, dust, chemicals, and exposure to UV radiation can impact the tensioner’s performance and durability. Choose a tensioner that is designed to withstand the specific environmental challenges of the application.

Refer to the manufacturer’s guidelines and recommendations for selecting and sizing the tensioner. Manufacturers often provide technical data, specifications, and selection guides that assist in choosing the appropriate tensioner for specific belt applications. Follow their recommendations to ensure compatibility and optimal performance.

It is important to note that the selection and sizing of belt tensioners may require technical expertise and consideration of specific application requirements. If in doubt, consult with belt tensioner manufacturers or industry experts who can provide further guidance based on their knowledge and experience.

In summary, when selecting and sizing belt tensioners for specific belt applications, consider the belt type and size, system requirements, tensioner type, design and mounting, load capacity, environmental conditions, and manufacturer recommendations. By carefully evaluating these factors, you can choose a suitable tensioner that ensures proper tensioning, reliable operation, and extended belt life in the belt-driven system.

What is the impact of proper belt tensioning on the lifespan and performance of belts?

Proper belt tensioning has a significant impact on the lifespan and performance of belts. Maintaining the correct tension in belts is crucial for optimal power transmission, minimizing slippage, reducing wear, and ensuring reliable operation. Here’s a detailed explanation of the impact of proper belt tensioning:

- Prevents Slippage:

- Reduces Wear and Friction:

- Ensures Optimal Power Transmission:

- Reduces Maintenance Requirements:

- Enhances Belt Lifespan:

- Improves System Reliability:

Proper belt tensioning prevents slippage between the belt and the pulleys or sheaves it is running on. When belts slip, power transmission efficiency decreases, and the belt can wear rapidly. By applying the correct tension, the belt grips the pulleys or sheaves firmly, ensuring efficient power transfer and minimizing slippage, which can lead to improved performance and energy efficiency.

When belts are improperly tensioned, excessive wear and friction can occur. Insufficient tension can cause the belt to slip and slide on the pulleys, generating heat and increasing friction between the belt and the pulley surfaces. This friction leads to premature wear of the belt and the pulleys, reducing their lifespan. On the other hand, excessive tension can put excessive stress on the belt, leading to accelerated wear and potential damage. Proper belt tensioning helps to minimize wear and friction, extending the lifespan of belts and associated components.

Correct tensioning of belts ensures optimal power transmission from the driving pulley to the driven pulley. When belts are properly tensioned, they can efficiently transfer the required power without energy losses due to slippage or excessive tension. This results in improved overall system performance, as the transmitted power is effectively utilized for driving various components or performing specific tasks.

Proper belt tensioning can help reduce maintenance requirements and associated costs. When belts are correctly tensioned, they experience less wear, require fewer adjustments, and have a lower chance of failure or premature replacement. By maintaining the appropriate tension, the need for frequent belt replacements and unplanned downtime due to belt-related issues can be significantly minimized, contributing to improved productivity and cost savings.

The lifespan of belts is directly influenced by proper tensioning. When belts are under the correct tension, they experience less stress, wear, and fatigue. This can prolong the lifespan of the belt, reducing the frequency of replacements and associated costs. Additionally, proper tensioning helps to distribute the load evenly across the belt, preventing localized wear and extending the overall durability of the belt.

Proper belt tensioning contributes to the overall reliability of belt-driven systems. By maintaining the correct tension, the risk of unexpected belt failures, slippage-related issues, and associated equipment downtime is significantly reduced. This ensures that the system operates reliably, minimizing interruptions in production or operation and enhancing overall system efficiency and performance.

In summary, proper belt tensioning plays a vital role in maximizing the lifespan and performance of belts. It prevents slippage, reduces wear and friction, ensures optimal power transmission, reduces maintenance requirements, enhances belt lifespan, and improves system reliability. By following manufacturer recommendations and using appropriate tensioning techniques, operators can optimize belt performance, minimize downtime, and achieve efficient and reliable operation of belt-driven systems.

Can you describe the various types of belt tensioners, such as automatic or manual tensioners?

There are various types of belt tensioners available, each designed to fulfill specific requirements in maintaining belt tension. Here’s a description of the different types of belt tensioners:

- Manual Belt Tensioners:

- Automatic Belt Tensioners:

- Hydraulic Belt Tensioners:

- Eccentric Belt Tensioners:

- Idler Pulley Tensioners:

Manual belt tensioners are the most basic type and require manual adjustment to set and maintain the desired tension. They typically consist of an adjustable arm or bracket that can be moved to increase or decrease the tension in the belt. Manual tensioners are commonly used in applications where tension adjustments are infrequent or can be easily accessed for manual adjustment. They are simple, cost-effective, and widely used in various industries.

Automatic belt tensioners, also known as self-adjusting or spring-loaded tensioners, are designed to maintain the proper tension automatically. They incorporate a spring mechanism that applies constant tension to the belt, compensating for belt elongation and wear over time. Automatic tensioners are commonly used in applications where frequent manual adjustments are impractical or where consistent tension control is essential. They provide convenience, minimize maintenance requirements, and ensure optimal tension without the need for manual intervention.

Hydraulic belt tensioners utilize hydraulic pressure to maintain belt tension. They consist of a hydraulic cylinder or piston that applies force to the tensioner arm, adjusting the tension in the belt. Hydraulic tensioners are commonly used in applications with high load requirements or variable operating conditions. They provide precise tension control, can compensate for changes in temperature and load, and are often employed in heavy-duty industrial machinery and automotive applications.

Eccentric belt tensioners use an eccentric mechanism to adjust the tension in the belt. They typically feature an eccentric pulley or roller that can be rotated to increase or decrease the tension. Eccentric tensioners are commonly used in applications where precise tension adjustments are required, such as high-performance engines or systems with specific belt tension specifications. They offer fine-tuning capabilities and are often found in automotive racing, performance tuning, and specialized machinery.

Idler pulley tensioners, also known as fixed tensioners or idler pulley assemblies, are a type of belt tensioner that utilizes an idler pulley to maintain tension. They are typically positioned on the slack side of the belt, providing guidance and tension control. Idler pulley tensioners are commonly used in applications where a fixed tension is desired, and the tensioning capability is provided by other components in the system, such as an automatic tensioner or an adjustable drive pulley.

In addition to these types, there are also specialized belt tensioners designed for specific applications or industries, such as torsional vibration dampers used in automotive engines to reduce vibrations, or belt tensioners with built-in dampening mechanisms to minimize noise in certain applications.

Overall, the choice of belt tensioner depends on factors such as the application requirements, load conditions, frequency of tension adjustments, and the desired level of automation and control. Selecting the appropriate type of belt tensioner is crucial to maintaining optimal belt tension and ensuring the efficient and reliable operation of belt-driven systems.

editor by CX 2024-03-15

China factory Auto Pulley Assy 1145A055 Timing Belt Tensioner as thru axle

Product Description

Auto Pulley Assy 1145A055 Timing Belt Tensioner

Product Specification:

| Parts OEM No.: | 1145A055 |

| Apply To: |

For car |

| Brand: | FENGMING OR OEM |

| Condition: | Brand New |

| Stock Availability: | Yes |

| Minimum Order QTY | 10PCS |

| OEM Order Acceptability: | Yes |

| Small order Lead Time: | 3-7 days |

| Large Order Lead Time: | 15-30 days |

| Quality Warranty | 12 months |

| PACKAGING | As original or as customer’s request, FENG MING PACKING |

| Payment Methods: | Paypal, Western Union, Bank T/T, L/C |

| Shipment Methods: | DHL, UPS, TNT, FedEx, Aramex, EMS, Air Cargo, Sea Cargo |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Car Make: | Car |

|---|---|

| Car Model: | Car |

| Part Number: | 1145A055 |

| Quality: | 100% |

| MOQ: | 10 |

| Delivery Time: | Within 3-7 Working Days |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you provide guidance on the selection and sizing of belt tensioners for specific belt applications?

When selecting and sizing belt tensioners for specific belt applications, several factors need to be considered to ensure optimal performance and longevity. Here’s a detailed guidance on the selection and sizing of belt tensioners:

- Belt Type and Size:

- System Requirements:

- Tensioner Type:

- Tensioner Design and Mounting:

- Tensioner Load Capacity:

- Environmental Considerations:

- Manufacturer Recommendations:

Start by identifying the type and size of the belt used in the application. Belts can vary in terms of width, length, profile (V-belt, timing belt, etc.), and construction material (rubber, polyurethane, etc.). The tensioner should be compatible with the specific belt type and size to ensure proper fit and functionality.

Consider the requirements of the belt-driven system. Evaluate factors such as the desired tension level, operating speed, load conditions, and environmental factors. The tensioner should be capable of providing the required tension force while accommodating the system’s operating parameters.

Choose the appropriate tensioner type based on the application’s needs. Common types include automatic tensioners, idler pulley tensioners, spring-loaded tensioners, and hydraulic tensioners. Each type has its advantages and limitations, so select the one that best suits the specific belt application.

Consider the design and mounting requirements of the tensioner. Evaluate the space availability, mounting configuration, and alignment with other components in the belt drive system. Some tensioners offer adjustable mounting positions or different design variations to accommodate various installation scenarios.

Check the load capacity of the tensioner to ensure it can handle the expected loads and forces in the belt system. Consider factors such as the belt tension, shock loads, and dynamic forces. The tensioner should have adequate load capacity to prevent premature wear or failure under normal operating conditions.

Assess the environmental conditions in which the tensioner will operate. Factors such as temperature extremes, moisture, dust, chemicals, and exposure to UV radiation can impact the tensioner’s performance and durability. Choose a tensioner that is designed to withstand the specific environmental challenges of the application.

Refer to the manufacturer’s guidelines and recommendations for selecting and sizing the tensioner. Manufacturers often provide technical data, specifications, and selection guides that assist in choosing the appropriate tensioner for specific belt applications. Follow their recommendations to ensure compatibility and optimal performance.

It is important to note that the selection and sizing of belt tensioners may require technical expertise and consideration of specific application requirements. If in doubt, consult with belt tensioner manufacturers or industry experts who can provide further guidance based on their knowledge and experience.

In summary, when selecting and sizing belt tensioners for specific belt applications, consider the belt type and size, system requirements, tensioner type, design and mounting, load capacity, environmental conditions, and manufacturer recommendations. By carefully evaluating these factors, you can choose a suitable tensioner that ensures proper tensioning, reliable operation, and extended belt life in the belt-driven system.

What is the impact of proper belt tensioning on the lifespan and performance of belts?

Proper belt tensioning has a significant impact on the lifespan and performance of belts. Maintaining the correct tension in belts is crucial for optimal power transmission, minimizing slippage, reducing wear, and ensuring reliable operation. Here’s a detailed explanation of the impact of proper belt tensioning:

- Prevents Slippage:

- Reduces Wear and Friction:

- Ensures Optimal Power Transmission:

- Reduces Maintenance Requirements:

- Enhances Belt Lifespan:

- Improves System Reliability:

Proper belt tensioning prevents slippage between the belt and the pulleys or sheaves it is running on. When belts slip, power transmission efficiency decreases, and the belt can wear rapidly. By applying the correct tension, the belt grips the pulleys or sheaves firmly, ensuring efficient power transfer and minimizing slippage, which can lead to improved performance and energy efficiency.

When belts are improperly tensioned, excessive wear and friction can occur. Insufficient tension can cause the belt to slip and slide on the pulleys, generating heat and increasing friction between the belt and the pulley surfaces. This friction leads to premature wear of the belt and the pulleys, reducing their lifespan. On the other hand, excessive tension can put excessive stress on the belt, leading to accelerated wear and potential damage. Proper belt tensioning helps to minimize wear and friction, extending the lifespan of belts and associated components.

Correct tensioning of belts ensures optimal power transmission from the driving pulley to the driven pulley. When belts are properly tensioned, they can efficiently transfer the required power without energy losses due to slippage or excessive tension. This results in improved overall system performance, as the transmitted power is effectively utilized for driving various components or performing specific tasks.

Proper belt tensioning can help reduce maintenance requirements and associated costs. When belts are correctly tensioned, they experience less wear, require fewer adjustments, and have a lower chance of failure or premature replacement. By maintaining the appropriate tension, the need for frequent belt replacements and unplanned downtime due to belt-related issues can be significantly minimized, contributing to improved productivity and cost savings.

The lifespan of belts is directly influenced by proper tensioning. When belts are under the correct tension, they experience less stress, wear, and fatigue. This can prolong the lifespan of the belt, reducing the frequency of replacements and associated costs. Additionally, proper tensioning helps to distribute the load evenly across the belt, preventing localized wear and extending the overall durability of the belt.

Proper belt tensioning contributes to the overall reliability of belt-driven systems. By maintaining the correct tension, the risk of unexpected belt failures, slippage-related issues, and associated equipment downtime is significantly reduced. This ensures that the system operates reliably, minimizing interruptions in production or operation and enhancing overall system efficiency and performance.

In summary, proper belt tensioning plays a vital role in maximizing the lifespan and performance of belts. It prevents slippage, reduces wear and friction, ensures optimal power transmission, reduces maintenance requirements, enhances belt lifespan, and improves system reliability. By following manufacturer recommendations and using appropriate tensioning techniques, operators can optimize belt performance, minimize downtime, and achieve efficient and reliable operation of belt-driven systems.

How do belt tensioners differ from other components in maintaining belt tension?

Belt tensioners play a distinct role in maintaining belt tension compared to other components in belt drive systems. Here’s a detailed explanation of how belt tensioners differ from other components:

1. Tension Adjustment:

Belt tensioners are specifically designed to provide an adjustable means of maintaining the proper tension in the belt. They are equipped with mechanisms such as springs, adjustable arms, or brackets that allow for easy tension adjustment. Other components in belt drive systems, such as pulleys or idlers, do not have this specific functionality and rely on external means, such as manual adjustment or fixed positioning, to maintain tension.

2. Active Tension Control:

Belt tensioners actively control and apply force to the belt to maintain tension. They are designed to compensate for belt elongation, thermal expansion, and other factors that can affect tension over time. By applying the appropriate tension, belt tensioners help to prevent belt slippage and maintain efficient power transmission. In contrast, other components, such as fixed pulleys or idlers, do not actively control tension and rely on the initial tension set during installation.

3. Dynamic Tension Compensation:

Belt tensioners are capable of dynamically adjusting the tension in response to changes in operating conditions. For example, in automotive applications, belt tensioners can compensate for variations in engine speed, temperature fluctuations, and belt wear. They can adapt to these changes and maintain the optimal tension level. Other components, such as fixed pulleys or idlers, do not possess this dynamic tension adjustment capability.

4. Vibration and Noise Damping:

Belt tensioners often incorporate features to dampen vibrations and reduce noise in the belt drive system. They act as shock absorbers, absorbing and dissipating vibrations, which helps to minimize belt flutter and reduce noise levels. Other components, such as fixed pulleys or idlers, do not typically have built-in vibration and noise damping properties.

5. Positioning on Slack Side:

Belt tensioners are typically positioned on the slack side of the belt, between the driving pulley and the driven pulley. This positioning allows them to apply tension to the belt where it is needed most, helping to maintain proper engagement and prevent slippage. In contrast, other components, such as fixed pulleys or idlers, are positioned on the tight side of the belt and primarily serve to guide and support the belt.

6. Component Integration:

Belt tensioners are standalone components that are specifically designed for tensioning belts. They are often integrated into the belt drive system as a separate unit, allowing for easy installation, adjustment, and replacement. Other components, such as pulleys or idlers, serve different functions in the system and may be integrated into other mechanisms or structures.

In summary, belt tensioners differ from other components in belt drive systems in their ability to provide adjustable tension control, dynamic tension compensation, vibration and noise damping capabilities, specific positioning on the slack side of the belt, and as standalone components designed solely for tensioning belts. These features make belt tensioners essential for maintaining optimal tension and ensuring the efficient and reliable operation of belt drive systems.

editor by CX 2024-02-25

China supplier Vkm62002 Auto Timing Chain Belt Tensioner Pulley for CZPT 11955-6n202 11955-6n20b 11955-8j000 11955-Ja00b manufacturer

Product Description

Detailed Photos

VKM62

ROVER : PQG 1A

GATES : T38242

HK : H481

HUTCHINSON : T5711

INA : F210685100

BMW : 11281717188

BMW : 1717188

DAYCO : APV3571

INA : 534 0571 1

RUVILLE : 56987

LEXUS : 166200Y571

LEXUS : 166257171

TOYOTA : 166200Y571

TOYOTA : 166257171

DAYCO : APV2784

FEBI BILSTEIN : 31255

GATES : T38278

INA :

HONDA : 31170-PNA-003

HONDA : 31170-PNA-013

HONDA : 31170-PNA-571

INA :

IPD : 15-3557

JAPANPARTS : TS-H02

JAPKO : 128H02

KM International : FI16960

HYUNDAI : 25281-37101

HYUNDAI : 25281-37120

KIA : 2528137101

DAYCO : APV2996

GATES : 38489

GATES : T38489

HUTCHINSON : T0428

INA : 534571610

SUBARU : 23769AA000

SUBARU : 23769AA001

SUBARU : 23769AA002

SUBARU : 23769AA003

INA :

IPD : 15-4234

JAPANPARTS : BE-342

KAVO PARTS : DTE-4532

FORD : 1449043

FORD : 6M34 6K254 AA

MAZDA : WE01-12-700

Advantages

1. Customized Brand

2. High quality

3. Competitive price

4. On-time delivery

5. CZPT color box packing or according to the client’s requirements

6. More reliable and stable, durable in use, long operating life

7. Genuine parts, strict QC system, quality guarantee

8. Durable use

9. Adopted superior material, ensure the product has a super hardness, high impact resistance, and abrasion resistance

What we can do?

To help customers save time and cost, we supply a one-stop service.

1. select qualified product factory

2. gather goods from different factory

3. inspect the quality

4. shipping service

5. design service, we have professional designers who can help customers design the package.

Belt Tensioner, belt tensioner pulley, timing belt tensioner, automatic belt tensioner, belt pulley, timing pulley, idler pulley, engine pulley, idler pulley assembly, tensioner & idler pulley, belt idler pulley, drive belt idler, pulley, tensioner, tensioner bearing, tensioner bearing replacement

Company Profile

We are a professional supplier of auto bearings, our products include wheel bearing, hub assembly, clutch release bearing, belt tensioner, etc. We supply one-stop service for customers. To help customers save time and cost, we will help customers gather products from many different suppliers and inspect the quality. If you have any demand, please contact us in time, we will ensure the best price and the highest quality

Packaging & Shipping

| Packaging Details | 1 piece in a single box 50 boxes in a carton 20 cartons in a pallet |

| Nearest Port | ZheJiang or HangZhou |

| Lead Time | For stock parts: 1-5 days. If no stock parts: <200 pcs: 15-30 days ≥200 pcs: to be negotiated. |

FAQ

If you have any other questions, please feel free to contact us as follows:

Q: Why did you choose us?

1. We provide the best quality bearings with reasonable prices, low friction, low noise, and long service life.

2. With sufficient stock and fast delivery, you can choose our freight forwarder or your freight forwarder.

Q: Do you accept small orders?

100% quality check, once your bearings are standard size bearings, even one, we also accept.

Q: How long is your delivery time?

Generally speaking, if the goods are in stock, it is 1-3 days. If the goods are out of stock, it will take 6-10 days, depending on the quantity of the order.

Q: Do you provide samples? Is it free or extra?

Yes, we can provide a small number of free samples.

Q: What should I do if I don’t see the type of bearings I need?

We have too many bearing series numbers. Just send us the inquiry and we will be very happy to send you the bearing details.

Q: Could you accept OEM and customize it?

A: Yes, we can customize for you according to the sample or drawing, but, pls provide us technical data, such as dimensions and marks.

Contact Us

| After-sales Service: | 1 Year / 30000-50000kms |

|---|---|

| Warranty: | 1 Year / 30000-50000kms |

| Type: | Tensioner Bearing |

| Material: | Chrome Steel |

| Tolerance: | P0/P6/P5 |

| Certification: | ISO9001, TS16949 |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is the role of belt tensioner materials and coatings in performance and longevity?

Belt tensioner materials and coatings play a crucial role in the performance and longevity of belt tensioners. The choice of materials and coatings directly impacts the tensioner’s ability to withstand the forces and loads encountered in belt-driven systems, resist wear and corrosion, and maintain consistent performance over time. Here’s a detailed explanation of the role of belt tensioner materials and coatings in performance and longevity:

- Strength and Durability:

- Wear Resistance:

- Corrosion Resistance:

- Friction Reduction:

- Temperature Stability:

- Lubrication Enhancement:

- Noise and Vibration Damping:

The materials used in belt tensioners need to possess high strength and durability to withstand the mechanical stresses and loads imposed on them. Tensioner components are subjected to continuous movement and contact with the belt, which can lead to wear, fatigue, and potential failure. High-strength materials, such as hardened steels or alloys, are commonly used to ensure the tensioner’s structural integrity and longevity.

Belt tensioners are exposed to friction and wear as they come into contact with the belt during operation. Materials with excellent wear resistance properties, such as hardened surfaces or wear-resistant coatings, are employed to minimize the wear rate and extend the tensioner’s lifespan. These materials and coatings help maintain optimal contact between the tensioner and the belt, reducing the risk of belt slippage and premature failure.

In certain environments, belt tensioners may be exposed to corrosive substances, moisture, or contaminants, which can lead to corrosion and degradation of the tensioner components. Corrosion-resistant materials, such as stainless steel or corrosion-resistant alloys, are often utilized to protect the tensioner against corrosive elements. Additionally, coatings like zinc plating or other protective finishes can be applied to enhance the tensioner’s corrosion resistance.

Reducing friction between the tensioner and the belt is essential for minimizing wear and maintaining consistent tension. Materials or coatings with low friction coefficients can help reduce the frictional forces and energy losses associated with the tensioner’s operation. By reducing friction, these materials and coatings contribute to improved efficiency, reduced heat generation, and increased longevity of the tensioner and the entire belt-driven system.

Belt tensioners are exposed to a wide range of operating temperatures, including both high and low extremes. Materials with good temperature stability and resistance to thermal degradation are essential for reliable tensioner performance. Heat-resistant alloys, high-temperature plastics, or thermal barrier coatings may be utilized to ensure that the tensioner maintains its mechanical properties and functionality under elevated temperatures.

Some tensioner materials or coatings are designed to enhance lubrication and reduce friction between moving parts. They may have self-lubricating properties or be compatible with specific lubricants used in the belt-driven system. These materials and coatings help reduce wear, heat generation, and the need for external lubrication, contributing to improved performance and extended longevity of the tensioner.

Belt tensioners can generate noise and vibration during operation, which can affect the comfort and performance of the belt-driven system. Certain materials or coatings can help dampen vibrations and reduce noise levels, improving the overall system’s performance and minimizing potential issues associated with excessive noise or vibrations.

In summary, the choice of belt tensioner materials and coatings is critical for ensuring optimal performance and longevity. Materials with high strength and durability, wear resistance, corrosion resistance, friction reduction, temperature stability, lubrication enhancement, and noise/vibration damping properties contribute to the tensioner’s ability to withstand the operational demands of belt-driven systems. By selecting appropriate materials and coatings, manufacturers can enhance the reliability, durability, and overall efficiency of belt tensioners, leading to extended service life and improved performance of the belt-driven systems they are used in.

What are the typical signs of improper belt tension, and how can belt tensioners address these issues?

Improper belt tension can lead to various issues in belt-driven systems. Recognizing the signs of improper tension is crucial for identifying and addressing potential problems. Belt tensioners play a crucial role in addressing these issues by adjusting and maintaining the proper tension in the belts. Here’s a detailed explanation of the typical signs of improper belt tension and how belt tensioners can address these issues:

- Slippage:

- Excessive Wear:

- Noise and Vibration:

- Overheating:

- Premature Belt Failure:

- Reduced Power Transmission Efficiency:

Slippage occurs when the belt slips on the pulleys instead of maintaining a firm grip. It can be caused by insufficient tension. Signs of slippage include a noticeable decrease in power transmission efficiency, a burning smell from friction, or visible wear on the belt and pulleys. Belt tensioners address slippage by applying the necessary force to increase the tension, improving the grip between the belt and the pulleys and minimizing slippage.

Improper tension can cause excessive wear on belts, pulleys, and other components. Insufficient tension may lead to belt slipping, resulting in accelerated wear. On the other hand, excessive tension can cause excessive stress and strain on the belt, leading to premature wear and potential damage. Belt tensioners help address excessive wear by adjusting the tension to the manufacturer’s recommended range, ensuring proper belt engagement and minimizing wear on the belt and associated components.

Improper belt tension can contribute to increased noise and vibration levels in the system. Insufficient tension may cause belt flapping or fluttering, leading to vibrations and noise. Excessive tension can create excessive forces and induce resonance, resulting in vibrations and noise as well. Belt tensioners address these issues by maintaining the correct tension, minimizing belt movement, reducing vibrations, and lowering noise levels, resulting in smoother and quieter operation.

Inadequate belt tension can cause overheating due to increased friction between the belt and the pulleys. Overheating may manifest as excessive heat radiating from the belt or pulleys, discoloration of the belt, or even belt degradation. Belt tensioners help address overheating by maintaining the proper tension, ensuring efficient power transmission and minimizing friction, which in turn reduces heat generation and helps prevent overheating issues.

Improper tension significantly increases the risk of premature belt failure. Insufficient tension can lead to belt slippage, accelerated wear, and reduced belt lifespan. Excessive tension can cause excessive stress and fatigue, leading to belt breakage or premature damage. Belt tensioners address these issues by maintaining the correct tension, distributing the load evenly across the belt, minimizing stress, and promoting longer belt life.

Improper belt tension can result in reduced power transmission efficiency. Insufficient tension leads to belt slipping, reducing the amount of power transferred from the driving pulley to the driven pulley. Excessive tension can cause increased friction and energy losses. Belt tensioners address these issues by ensuring the proper tension, maximizing the grip between the belt and the pulleys, and optimizing power transmission efficiency.

In summary, improper belt tension can manifest through signs such as slippage, excessive wear, noise and vibration, overheating, premature belt failure, and reduced power transmission efficiency. Belt tensioners address these issues by adjusting the tension to the recommended range, minimizing slippage, reducing wear, damping vibrations, preventing overheating, promoting longer belt life, and optimizing power transmission efficiency. Regular inspection and adjustment of belt tension using appropriate tensioners are essential for maintaining optimal belt performance and preventing potential issues.

What is a belt tensioner, and what role does it play in mechanical systems?

A belt tensioner is a mechanical component used in belt drive systems to maintain proper tension in the belt. It plays a crucial role in ensuring efficient power transmission, preventing belt slippage, and extending the lifespan of the belt and other related components. Here’s a detailed explanation of the belt tensioner and its role in mechanical systems:

A belt tensioner is typically a pulley or idler mechanism that is designed to apply force on the belt to maintain the desired tension. It is usually mounted on an adjustable arm or bracket, allowing for easy tension adjustment. The tensioner is positioned in such a way that it applies pressure to the belt on the slack side, which is the portion of the belt between the driving pulley and the driven pulley.

The primary role of a belt tensioner is to compensate for any stretching or elongation of the belt that may occur over time due to wear, temperature changes, or other factors. By maintaining the proper tension in the belt, the tensioner helps to prevent belt slippage, which can lead to a loss of power transmission efficiency and potential damage to the belt and pulleys.

In addition to maintaining tension, a belt tensioner also helps to dampen vibrations and reduce noise in the belt drive system. It acts as a shock absorber, absorbing and dissipating vibrations and preventing excessive belt flutter or oscillation. This contributes to smoother operation and improved system reliability.

Furthermore, a belt tensioner assists in prolonging the lifespan of the belt and other components in the drive system. Adequate tension reduces the risk of premature wear and fatigue on the belt, pulleys, and bearings. It also helps to distribute the load evenly across the belt, minimizing localized stress and ensuring optimal power transmission.

When installing a belt tensioner, it’s important to follow the manufacturer’s guidelines and recommendations. Proper positioning, alignment, and adjustment of the tensioner are essential to achieve the desired tension and ensure the efficient operation of the belt drive system.

In summary, a belt tensioner is a critical component in mechanical systems utilizing belt drives. It maintains the appropriate tension in the belt, prevents slippage, reduces vibrations and noise, and contributes to the longevity and reliability of the system. By incorporating a belt tensioner, engineers and designers can optimize the performance and efficiency of belt-driven machinery and equipment.

editor by CX 2023-11-14

China Best Sales Htd3m Htd5m S3m S5m P3m T5 At10 2gt 3gt 5gt Timing Belt Pulley for Packaging Machinery pulley drive

Product Description

Quick Details

Warranty:3 years

Applicable Industries:Manufacturing Plant, Retail, Construction works , Advertising Company

Customized support:OEM

Type:TIMING

Material:Aluminum ALLOY

Place of Origin:ZheJiang , China

Product name:Aluminium timing belt pulley

Color:Silver

Surface treatment:Anodic Oxidation/Mill finish

Size:Customized Sizes

Timing Pulley Type:Open Timing Pulley

Usage:Automatic mechanical equipment

Packing:Carton packing

Belt Width:10mm

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Printer Cutter |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Curved Gear |

| Material: | Aluminum |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How to use the pulley system

Using a pulley system is a great way to move things around your home, but how do you use a pulley system? Let’s look at the basic equations that describe a pulley system, the types of pulleys, and some safety considerations when using pulleys. Here are some examples. Don’t worry, you’ll find all the information you need in one place!

Basic equations of pulley systems

The pulley system consists of pulleys and chords. When the weight of the load is pulled through the rope, it slides through the groove and ends up on the other side. When the weight moves, the applied force must travel nx distance. The distance is in meters. If there are four pulleys, the distance the rope will travel will be 2×24. If there are n pulleys, the distance traveled by the weight will be 2n – 1.

The mechanical advantage of the pulley system increases with distance. The greater the distance over which the force is applied, the greater the leverage of the system. For example, if a set of pulleys is used to lift the load, one should be attached to the load and the other to the stand. The load itself does not move. Therefore, the distance between the blocks must be shortened, and the length of the line circulating between the pulleys must be shortened.

Another way to think about the acceleration of a pulley system is to think of ropes and ropes as massless and frictionless. Assuming the rope and pulley are massless, they should have the same magnitude and direction of motion. However, in this case the quality of the string is a variable that is not overdone. Therefore, the tension vector on the block is labeled with the same variable name as the pulley.

The calculation of the pulley system is relatively simple. Five mechanical advantages of the pulley system can be found. This is because the number of ropes supporting the load is equal to the force exerted on the ropes. When the ropes all move in the same direction, they have two mechanical advantages. Alternatively, you can use a combination of movable and fixed pulleys to reduce the force.

When calculating forces in a pulley system, you can use Newton’s laws of motion. Newton’s second law deals with acceleration and force. The fourth law tells us that tension and gravity are in equilibrium. This is useful if you need to lift heavy objects. The laws of motion help with calculations and can help you better understand pulley systems.

Types of pulleys

Different types of pulleys are commonly used for various purposes, including lifting. Some pulleys are flexible, which means they can move freely around a central axis and can change the direction of force. Some are fixed, such as hinges, and are usually used for heavier loads. Others are movable, such as coiled ropes. Whatever the purpose, pulleys are very useful in raising and lowering objects.

Pulleys are common in many different applications, from elevators and cargo lift systems to lights and curtains. They are also used in sewing machine motors and sliding doors. Garage and patio doors are often equipped with pulleys. Rock climbers use a pulley system to climb rocks safely. These pulley systems have different types of pinions that allow them to balance weight and force direction.

The most common type of pulley is the pulley pulley system. The pulley system utilizes mechanical advantages to lift weight. Archimedes is thought to have discovered the pulley around 250 BC. in ancient Sicily. Mesopotamians also used pulleys, they used ropes to lift water and windmills. Pulley systems can even be found at Stonehenge.

Another type of pulley is called a compound pulley. It consists of a set of parallel pulleys that increase the force required to move large objects. This type is most commonly used in rock climbing and sailing, while composite pulleys can also be found in theater curtains. If you’re wondering the difference between these two types of pulleys, here’s a quick overview:

Mechanical Advantages of Pulley Systems

Pulley systems offer significant mechanical advantages. The ability of the system to reduce the effort required to lift weights increases with the number of rope loops. This advantage is proportional to the number of loops in the system. If the rope had only one loop, then a single weight would require the same amount of force to pull. But by adding extra cycles, the force required will be reduced.

The pulley system has the advantage of changing the direction of the force. This makes it easier to move heavy objects. They come in both fixed and mobile. Pulleys are used in many engineering applications because they can be combined with other mechanisms. If you want to know what a pulley can do, read on! Here are some examples. Therefore, you will understand how they are used in engineering.

Single-acting pulleys do not change direction, but compound pulleys do. Their mechanical advantage is six. The compound pulley system consists of a movable pulley and a fixed pulley. The mechanical advantage of the pulley system increases as the number of movable wheels decreases. So if you have two wheels, you need twice as much force to lift the same weight because you need a movable pulley.

The mechanical advantage of a pulley system can be maximized by adding more pulleys or rope lengths. For example, if you have a single pulley system, the mechanical advantage is one of the smallest. By using two or three pulleys, up to five times the mechanical advantage can be achieved. You can also gain up to ten times the mechanical advantage by using multiple pulley systems.

The use of a single movable pulley system also adds to the mechanical advantage of the pulley system. In this case, you don’t have to change the direction of the force to lift the weight. In contrast, a movable pulley system requires you to move the rope farther to generate the same force. Using a compound pulley system allows you to lift heavy loads with ease.

Safety Issues When Using Pulley Systems

Pulleys have an incredibly unique structure, consisting of a disc with a groove in the middle and a shaft running through it. A rope or cord is attached to one end of a pulley that turns when force is applied. The other end of the rope is attached to the load. This mechanical advantage means that it is much easier to pull an object using the pulley system than to lift the same object by hand.

Although pulley systems are a common part of many manufacturing processes, some employers do not train their workers to use them properly or install protection to prevent injury. It is important to wear proper PPE and follow standard laboratory safety practices during pulley system activities. Make sure any support structures are strong enough to handle the weight and weight of the rope or rope. If you do fall, be sure to contact your employer immediately.

editor by CX

2023-05-25

China Custom Industry Polyurethane Rubber Conveyor Teeth Timing Synchronous Pulley with Good quality

Product Description

PU Flex Timing Belt/PU Truly Unlimited Timing Belt

*Polyurethane belt loop energy,by a unique thermoset molding method.

*Substantial-top quality polyurethane content resistant to dress in the belt and tear tesistant suitable ties.

*One of the main wire to improve belt toughness,tensile stregth,so that the belt has very good dimensional balance.

*Polyurethane energy ring with small tolerances,can guarantee the precision of thickness and duration.

*All of the above functions make the ployurethane ring has a higher electricity with the bodily and chemical security.

Polyurethane belt has the adhering to homes:

*Mechanical properties *Chemical houses

Positive suit,synchronous,running Resistant to getting older,water solution,UVUVA,anti-ozne

Constant duration,no publish-elongation Working temperature:-30ºC-80ºC(brief time could

Low noise withstand 110ºC)

Wear resistant Resistant from easy oils,fats and petrol

Low-maintenance Resistant to some acids

Highly versatile

Belt speeds up to 80m/s

This spherical PU timing belt especially

appropriate for lower load synchronous transmission,

this sort of as:office automation technique and household appliances.

Connected Belt

one.Ring belt from the continuous metal core and the thermoplastic polyurethane substance,is a real no interface ring belt.

2.Ring belt to guarantee the attributes and procedure underneath higher load,this energy transmission belt for higher-speed and large load transfer.

3.Ring belt size could be from 1.seven hundred to 22.000 meters.

four.Ring belt can be personalized according to customer’s requirements of distinct designs,these kinds of as:AT20,AT10,T10,T5,AT5,HTD8M,STD8M…..

*Ring belt particular processing:

1.Tooth surface and nylon cloth

2.Can be rolled back again a special pattern grinding and drilling

3.can go over the back again of the belt thicking

About opening belt

*Opening belt completed with a continuous duration,the center and the sides parallel to the wire main.Regular roll size is fifty or one hundred meters.

*Open (PU) leather-based belt with a variety of diverse core choice,such as kevlar core,hugely versatile main(HF)large-efficiency(HP)and high toughness(HPF)

*Production tolerance of little dependable transmission and has a dimensional stability.The manufacturing approach or in the tooth and tooth include a layer of nylon to make sure that apps working in the specific characterstics of the exact same.Also thicker layer of polyurethane in the belt or the again of the crimson plastic to avert corrosion or high load.

Design Checklist

*Kinds of design to pick

MXL

| Spec. | Enamel | Spec. | Tooth | Spec. | Tooth | Spec. | Teeth | Spec. | Tooth | Spec. | Enamel | Spec. | Enamel | Spec. | Tooth |

| 26MXL | 33 | 36MXL | forty five | 37MXL | 46 | 38MXL | forty eight | 41MXL | fifty one | 46MXL | 58 | 53MXL | sixty six | 54MXL | 67 |

| 55MXL | 70 | 56MXL | seventy one | 57MXL | seventy two | 58MXL | seventy three | 59MXL | 74 | 60MXL | seventy five | 61MXL | seventy six | 63MXL | 79 |

| 64MXL | 82 | 65MXL | 83 | 71MXL | 89 | 72MXL | ninety | 73MXL | ninety two | 74MXL | 93 | 75MXL | ninety five | 76MXL | 96 |

| 77MXL | ninety seven | 78MXL | 98 | 80MXL | 100 | 81MXL | 102 | 82MXL | 103 | 84MXL | a hundred and five | 85MXL | 106 | 86MXL | 107 |

| 87MXL | a hundred and ten | 88MXL | 112 | 89MXL | 114 | 92MXL | 115 | 93MXL | 119 | 94MXL | 120 | 95MXL | 121 | 96MXL | 122 |

| 97MXL | 123 | 98MXL | 124 | 99MXL | one hundred twenty five | 100MXL | 126 | 101MXL | 127 | 102MXL | 128 | 105MXL | 132 | 107MXL | 134 |

| 109MXL | 136 | 112MXL | 140 | 114MXL | 143 | 115MXL | 144 | 116MXL | a hundred forty five | 120MXL | a hundred and fifty | 122MXL | 153 | 124MXL | 155 |

| 126MXL | 157 | 128MXL | 160 | 132MXL | one hundred sixty five | 140MXL | a hundred seventy five | 143MXL | 179 | 144MXL | one hundred eighty | 145MXL | 181 | 148MXL | 185 |

| 150MXL | 187 | 151MXL | 189 | 152MXL | a hundred ninety | 153MXL | 191 | 154MXL | 192 | 155MXL | 193 | 156MXL | 195 | 160MXL | 200 |

| 168MXL | 210 | 184MXL | 230 | 200MXL | 250 | 204MXL | 255 | 205MXL | 256 | 208MXL | 260 | 348MXL | 435 | 400DMXL | five hundred |

T10

| Spec. | Tooth | Spec. | Tooth | Spec. | Tooth | Spec. | Tooth | Spec. | Tooth | Spec. | Tooth | Spec. | Tooth | Spec. | Enamel |

| T10*260 | 26 | T10*three hundred | 30 | T10*330 | 33 | T10*370 | 37 | T10*390 | 39 | T10*four hundred | forty | T10*410 | 41 | T10*440 | 44 |

| T10*450 | forty five | T10*460 | 46 | T10*480 | forty eight | T10*500 | 50 | T10*510 | 51 | T10*530 | 53 | T10*540 | fifty four | T10*550 | fifty five |

| T10*560 | fifty six | T10*600 | sixty | T10*610 | sixty one | T10*620 | sixty two | T10*630 | sixty three | T10*650 | 65 | T10*660 | sixty six | T10*680 | 68 |

| T10*690 | 69 | T10*700 | 70 | T10*720 | 72 | T10*730 | 73 | T10*750 | seventy five | T10*780 | seventy eight | T10*800 | eighty | T10*810 | eighty one |

| T10*830 | eighty three | T10*840 | eighty four | T10*850 | eighty five | T10*860 | 86 | T10*880 | 88 | T10*890 | 89 | T10*900 | 90 | T10*910 | ninety one |

| T10*920 | ninety two | T10*950 | 95 | T10*960 | 96 | T10*970 | ninety seven | T10*980 | 98 | T10*1000 | 100 | T10*1571 | a hundred and one | T10*1050 | 105 |

| T10*1080 | 108 | T10*1100 | 110 | T10*1110 | 111 | T10*1140 | 114 | T10*1150 | 115 | T10*1200 | one hundred twenty | T10*1210 | 121 | T10*1240 | 124 |

| T10*1250 | a hundred twenty five | T10*1260 | 126 | T10*1280 | 128 | T10*1300 | one hundred thirty | T10*1320 | 132 | T10*1350 | one hundred thirty five | T10*1360 | 136 | T10*1390 | 139 |

| T10*1400 | 140 | T10*1410 | 141 | T10*1420 | 142 | T10*1440 | a hundred and forty four | T10*1450 | 145 | T10*1460 | 146 | T10*1500 | one hundred fifty | T10*1520 | 152 |

| T10*1560 | 156 | T10*1580 | 158 | T10*1600 | 160 | T10*1640 | 164 | T10*1700 | one hundred seventy | T10*1750 | one hundred seventy five | T10*1760 | 176 | T10*1780 | 178 |

| T10*1800 | 180 | T10*1850 | 185 | T10*1860 | 186 | T10*1880 | 188 | T10*1960 | 196 | T10*1980 | 198 | T10*2000 | two hundred | T10*2571 | 202 |

| T10*2100 | 210 | T10*2120 | 212 | T10*2160 | 216 | T10*2170 | 217 | T10*2200 | 220 | T10*2250 | 225 | T10*2500 | 250 | T10*2800 | 280 |

H

| Spec. | Teeth | Spec. | Tooth | Spec. | Tooth | Spec. | Enamel | Spec. | Tooth | Spec. | Tooth | Spec. | Teeth | Spec. | Tooth | Spec. | Teeth |

| 200H | 40 | 225H | 45 | 250H | 50 | 260H | fifty two | 270H | fifty four | 280H | fifty six | 300H | sixty | 315H | 63 | 330H | 66 |

| 350H | 70 | 390H | seventy eight | 420H | eighty four | 450H | 90 | 460H | 92 | 470H | ninety four | 480H | ninety six | 510H | 102 | 540H | 108 |

| 560H | 112 | 570H | 114 | 600H | one hundred twenty | 630H | 126 | 700H | 140 | 750H | one hundred fifty | 900H | one hundred eighty |

T2.five

| Spec. | Tooth | Spec. | Enamel | Spec. | Enamel | Spec. | Tooth | Spec. | Tooth | Spec. | Tooth | Spec. | Tooth | Spec. | Enamel |

| T2.5*a hundred and twenty | forty eight | T2.5*a hundred forty five | fifty eight | T2.5*a hundred and sixty | sixty four | T2.5*180 | seventy two | T2.5*182.5 | 73 | T2.5*200 | eighty | T2.5*215 | 86 | T2.5*240 | ninety six |

| T2.5*245 | ninety eight | T2.5*260 | 104 | T2.5*285 | 114 | T2.5*330 | 132 | T2.5*380 | 152 | T2.5*420 | 168 | T2.5*five hundred | 200 | T2.5*600 | 240 |

| T2.5*650 | 260 | T2.5*780 | 312 | T2.5*950 | 380 |

AT5

| Spec. | Enamel | Spec. | Teeth | Spec. | Tooth | Spec. | Tooth | Spec. | Teeth |

| AT5*375 | 75 | AT5*390 | seventy eight | AT5*455 | ninety one | AT5*490 | ninety eight | AT5*500 | one hundred |

AT10

| Spec. | Tooth | Spec. | Tooth | Spec. | Teeth | Spec. | Tooth | Spec. | Tooth | Spec. | Teeth | Spec. | Enamel | Spec. | Enamel |

| AT10*500 | 50 | AT10*600 | sixty | AT10*660 | sixty six | AT10*seven-hundred | 70 | AT10*730 | 73 | AT10*780 | 78 | AT10*800 | 800 | AT10*840 | eighty four |

| AT10*920 | 92 | AT10*960 | 96 | AT10*980 | 98 | AT10*1050 | 105 | AT10*1080 | 108 | AT10*1100 | 110 | AT10*1150 | one hundred fifteen | AT10*1200 | one hundred twenty |

| AT10*1210 | 121 | AT10*1250 | 125 | AT10*1280 | 128 | AT10*1300 | one hundred thirty | AT10*1350 | a hundred thirty five | AT1390 | 139 | AT10*1400 | one hundred forty | AT10*1480 | 148 |

| AT10*1600 | a hundred and sixty | AT10*1700 | one hundred seventy | AT10*1860 | 186 | AT10*1900 | one hundred ninety |

S3M

| Spec. | Enamel | Spec. | Tooth | Spec. | Teeth | Spec. | Tooth | Spec. | Tooth | Spec. | Teeth | Spec. | Tooth | Spec. | Teeth |

| S3M120 | forty | S3M144 | forty eight | S3M150 | 50 | S3M183 | sixty one | S3M192 | sixty four | S3M201 | 67 | S3M210 | 70 | S3M231 | seventy seven |

| S3M237 | 79 | S3M246 | 82 | S3M315 | one zero five | S3M357 | 119 | S3M418 | one hundred forty | S3M420 | one hundred forty | S3M432 | 144 | S3M453 | 151 |

| S3M459 | 153 | S3M486 | 162 | S3M492 | 164 | S3M504 | 168 | S3M510 | one hundred seventy | S3M513 | 171 | S3M519 | 173 | S3M525 | one hundred seventy five |

| S3M528 | 176 | S3M537 | 179 | S3M543 | 181 | S3M546 | 182 | S3M549 | 183 | S3M555 | 185 | S3M564 | 188 | S3M571 | 191 |

| S3M573 | 191 | S3M585 | 195 | S3M588 | 196 | S3M600 | 200 | S3M612 | 204 | S3M705 | 235 | S3M738 | 246 | S3M780 | 260 |

| A3M717 | 239 | D3M327 | 109 |

HTD3M

| Spec. | Teeth | Spec. | Tooth | Spec. | Teeth | Spec. | Teeth | Spec. | Tooth | Spec. | Enamel | Spec. | Tooth | Spec. | Tooth |

| 3M135 | forty five | 3M144 | forty eight | 3M171 | 57 | 3M174 | fifty eight | 3M177 | fifty nine | 3M189 | 63 | 3M195 | 65 | 3M207 | 69 |

| 3M225 | 75 | 3M228 | 76 | 3M243 | 81 | 3M255 | eighty five | 3M264 | 88 | 3M276 | ninety two | 3M288 | 96 | 3M294 | 98 |

| 3M300 | 100 | 3M312 | 104 | 3M315 | 105 | 3M324 | 108 | 3M336 | 112 | 3M345 | a hundred and fifteen | 3M357 | 119 | 3M360 | a hundred and twenty |

| 3M366 | 122 | 3M375 | a hundred twenty five | 3M384 | 128 | 3M402 | 134 | 3M420 | a hundred and forty | 3M423 | 141 | 3M435 | 145 | 3M456 | 152 |

| 3M459 | 153 | 3M462 | 154 | 3M468 | 156 | 3M471 | 157 | 3M483 | 161 | 3M486 | 162 | 3M495 | one hundred sixty five | 3M504 | 168 |

| 3M510 | 170 | 3M522 | 174 | 3M525 | 175 | 3M537 | 179 | 3M540 | a hundred and eighty | 3M549 | 183 | 3M555 | 185 | 3M564 | 188 |

| 3M573 | 191 | 3M606 | 202 | 3M657 | 219 | 3M669 | 223 | 3M693 | 231 | 3M699 | 233 | 3M708 | 236 | 3M720 | 240 |

| 3M738 | 246 | 3M879 | 293 | 3M1569 | 523 | 3M2040 | 680 |

*We also have design :L/XL/XXL/T5/AT3/H/PK/PJ/PH/DMB/DT5/DR/PL/MB/DAT10/DT10/S2M/S5M/5M/HTD2M/HTD5M/HTD14M/HTD8M,or as your requirment to make new model but need to pay out model cost,If you have no quantity,noted make sure you!

Application

About company

ZheJiang CZPT Transmission Tools Co.,Ltd. Was proven in March 2004,have 16 many years of production encounter.Local in No. eleven, Lane 243, Jiugan Road, Sijing Town, Xihu (West Lake) Dis. District, ZheJiang ,China.Primary offer in transmission belt and modular chain belt and many others.manufacturing quantity more than 50000 parts 1 calendar year.all types of rubber content,pvc and pu content and so forth.settle for specical creating as your requirment. We support personalized support.and delivery time most fastest 1day according to your orders.Firms adhering to the “integrity,quality,cost,and services first,constant innovation” organization philosophy,dedicated to offer higher high quality merchandise and substantial-quality service for the consumer,the firm continutes to expand the scale of growth,consumers through the country.

If you have fascinated,totally free time to get in touch with me please.

|

US $1-50 / Piece | |

1 Piece (Min. Order) |

###

| Certification: | CE |

|---|---|

| Pulley Sizes: | Custom |

| Manufacturing Process: | Casting |

| Material: | Alloy |

| Surface Treatment: | Custom |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

###

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Spec. | Teeth | Spec. | Teeth | Spec. | Teeth | Spec. | Teeth | Spec. | Teeth | Spec. | Teeth | Spec. | Teeth | Spec. | Teeth |

| 26MXL | 33 | 36MXL | 45 | 37MXL | 46 | 38MXL | 48 | 41MXL | 51 | 46MXL | 58 | 53MXL | 66 | 54MXL | 67 |

| 55MXL | 70 | 56MXL | 71 | 57MXL | 72 | 58MXL | 73 | 59MXL | 74 | 60MXL | 75 | 61MXL | 76 | 63MXL | 79 |

| 64MXL | 82 | 65MXL | 83 | 71MXL | 89 | 72MXL | 90 | 73MXL | 92 | 74MXL | 93 | 75MXL | 95 | 76MXL | 96 |

| 77MXL | 97 | 78MXL | 98 | 80MXL | 100 | 81MXL | 102 | 82MXL | 103 | 84MXL | 105 | 85MXL | 106 | 86MXL | 107 |

| 87MXL | 110 | 88MXL | 112 | 89MXL | 114 | 92MXL | 115 | 93MXL | 119 | 94MXL | 120 | 95MXL | 121 | 96MXL | 122 |

| 97MXL | 123 | 98MXL | 124 | 99MXL | 125 | 100MXL | 126 | 101MXL | 127 | 102MXL | 128 | 105MXL | 132 | 107MXL | 134 |

| 109MXL | 136 | 112MXL | 140 | 114MXL | 143 | 115MXL | 144 | 116MXL | 145 | 120MXL | 150 | 122MXL | 153 | 124MXL | 155 |

| 126MXL | 157 | 128MXL | 160 | 132MXL | 165 | 140MXL | 175 | 143MXL | 179 | 144MXL | 180 | 145MXL | 181 | 148MXL | 185 |

| 150MXL | 187 | 151MXL | 189 | 152MXL | 190 | 153MXL | 191 | 154MXL | 192 | 155MXL | 193 | 156MXL | 195 | 160MXL | 200 |

| 168MXL | 210 | 184MXL | 230 | 200MXL | 250 | 204MXL | 255 | 205MXL | 256 | 208MXL | 260 | 348MXL | 435 | 400DMXL | 500 |

###

| Spec. | Teeth | Spec. | Teeth | Spec. | Teeth | Spec. | Teeth | Spec. | Teeth | Spec. | Teeth | Spec. | Teeth | Spec. | Teeth |

| T10*260 | 26 | T10*300 | 30 | T10*330 | 33 | T10*370 | 37 | T10*390 | 39 | T10*400 | 40 | T10*410 | 41 | T10*440 | 44 |

| T10*450 | 45 | T10*460 | 46 | T10*480 | 48 | T10*500 | 50 | T10*510 | 51 | T10*530 | 53 | T10*540 | 54 | T10*550 | 55 |

| T10*560 | 56 | T10*600 | 60 | T10*610 | 61 | T10*620 | 62 | T10*630 | 63 | T10*650 | 65 | T10*660 | 66 | T10*680 | 68 |

| T10*690 | 69 | T10*700 | 70 | T10*720 | 72 | T10*730 | 73 | T10*750 | 75 | T10*780 | 78 | T10*800 | 80 | T10*810 | 81 |

| T10*830 | 83 | T10*840 | 84 | T10*850 | 85 | T10*860 | 86 | T10*880 | 88 | T10*890 | 89 | T10*900 | 90 | T10*910 | 91 |

| T10*920 | 92 | T10*950 | 95 | T10*960 | 96 | T10*970 | 97 | T10*980 | 98 | T10*1000 | 100 | T10*1010 | 101 | T10*1050 | 105 |

| T10*1080 | 108 | T10*1100 | 110 | T10*1110 | 111 | T10*1140 | 114 | T10*1150 | 115 | T10*1200 | 120 | T10*1210 | 121 | T10*1240 | 124 |

| T10*1250 | 125 | T10*1260 | 126 | T10*1280 | 128 | T10*1300 | 130 | T10*1320 | 132 | T10*1350 | 135 | T10*1360 | 136 | T10*1390 | 139 |

| T10*1400 | 140 | T10*1410 | 141 | T10*1420 | 142 | T10*1440 | 144 | T10*1450 | 145 | T10*1460 | 146 | T10*1500 | 150 | T10*1520 | 152 |

| T10*1560 | 156 | T10*1580 | 158 | T10*1600 | 160 | T10*1640 | 164 | T10*1700 | 170 | T10*1750 | 175 | T10*1760 | 176 | T10*1780 | 178 |

| T10*1800 | 180 | T10*1850 | 185 | T10*1860 | 186 | T10*1880 | 188 | T10*1960 | 196 | T10*1980 | 198 | T10*2000 | 200 | T10*2020 | 202 |

| T10*2100 | 210 | T10*2120 | 212 | T10*2160 | 216 | T10*2170 | 217 | T10*2200 | 220 | T10*2250 | 225 | T10*2500 | 250 | T10*2800 | 280 |

###